Main features:

250*250*300mm

Nozzle: 500°C

Platform: 200°C

Chamber: 200°C

Water cooling / Thermal insulation system

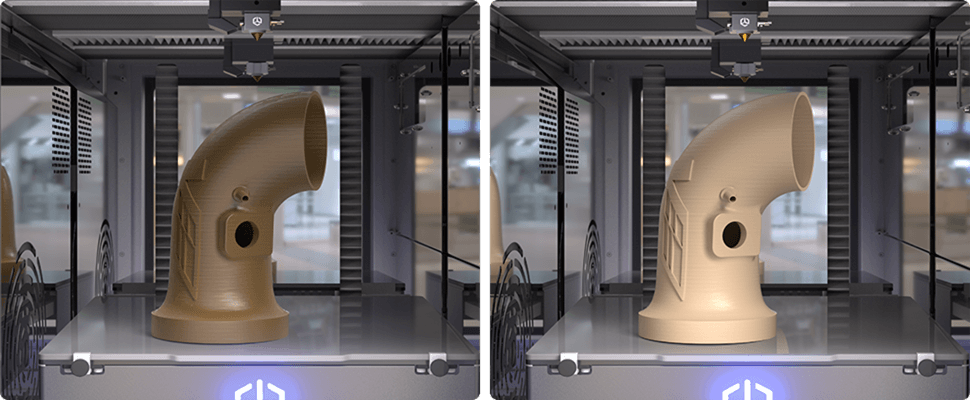

Why is a 180°C hot chamber important?

The room temperature of 180°C is necessary for the annealing treatment of PEEK material.

Therefore, after the device prints the PEEK pattern, it can be annealed directly in the device.

The advantages of doing so are:

(1) No need to remove the model from the platform to prevent the bottom of the model from losing adhesion to the platform.

(2) Avoids turning off and cooling the model to remove it. There is no exchange of hot and cold environments.

(3) After printing, the annealing treatment can be set directly in the printer without any delay.

180°C is the ideal temperature to print PEI material perfectly.

Temperature requirements of the printing environment:

(1) Usually set between 160°C and 200°C. The recommended environment temperature is 180°C.

(2) PEI has hygroscopic properties and can cause material degradation.

(3) PEI materials usually need annealing after forming.

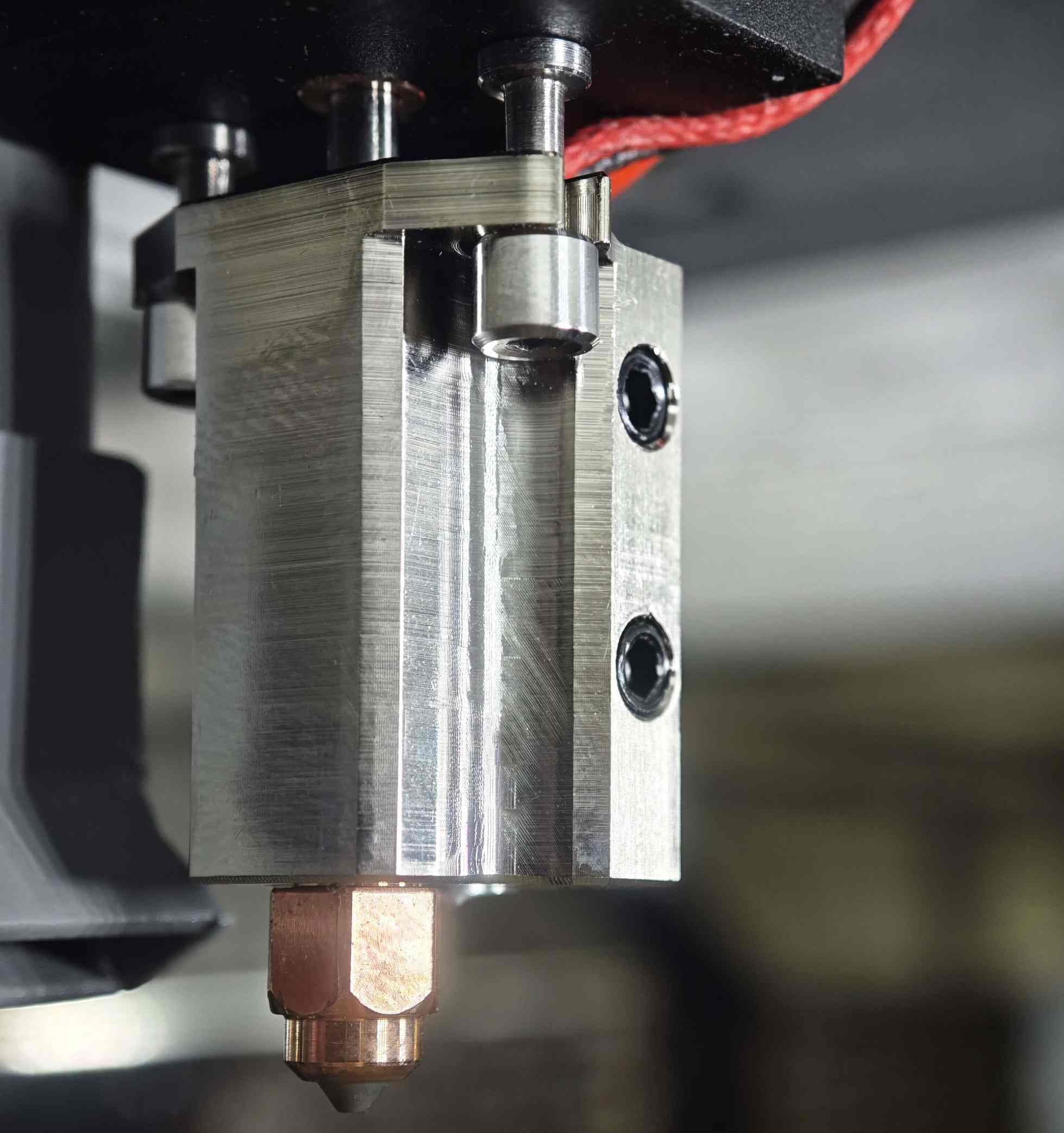

High Temperature Extrusion System

Double-tooth silicon carbide extruder.

Water cooling device required, replaceable in 30 seconds.

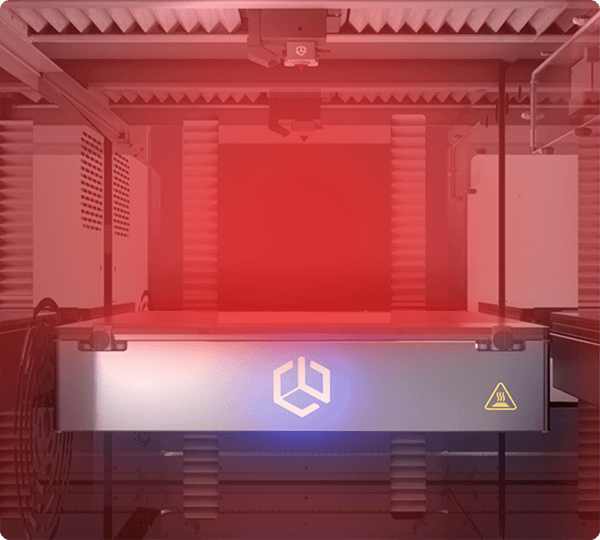

Uniformly Heated Chamber at 200°C.

Special device for 360° hot air circulation.

Thermal Insulation/Chamber Safety.

Aircraft-grade insulation materials, temperature controlled within 40°C.

High Temperature Platform 200°C

Ultra-flat platform of aircraft grade + polymer coating

Natural flatness 0.05mm

High-temperature flatness 0.1mm (chamber temperature 180°C)

No need for manual or automatic leveling

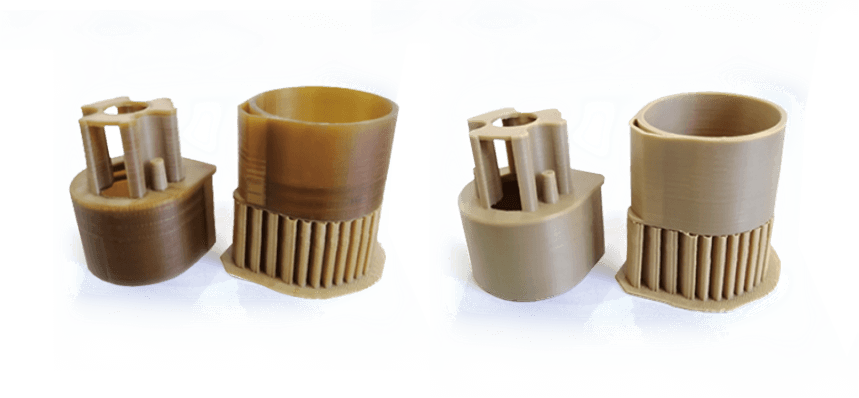

One-Stop Annealing Function

After printing, you do not need to detach the model from the platform.

You can select the 'direct annealing after printing' function for materials such as PEEK, PEI, etc.

Package contains: 1 x 3D Printer PEEK-250 - CreatBot