Worldwide express shipping

- My DHM

- +Products

- +Mechanical components

- +Profiles structural and accessories

- +Hardware and Screws

- +Industrial material

- +Robotics and Automation

- Motor driver

- Relays and switches

- Power supplies

- Modules and card expansions

- Fans

- Parts for cards

- Control cards

- Arduino boards

- Integrated computers and development boards

- Spies and warning lights

- Duet 3D

- Arduino compatible

- Optoelectronics

- Passive components

- Thermal management

- Video surveillance

- Sensors

- Batteries and Chargers

- Semiconductors

- PCB Prototyping

- Motors

- Data storage and connectivity

- CNC Machines

- +Electrical equipment

- +Extruder group - 3D printing

- +Print bed - 3D print

- +Filaments and 3D Resins

- PLA

- Special PLA

- Loaded

- PETG

- Co-polyesters

- PP - Polypropylene

- Eraser

- PA - Polyamide

- ASA

- ABS

- Special ABS

- PC - Polycarbonate

- PVA and supports

- HIPS

- SKIN contact

- PEI - Polyetherimide

- PMMA

- PPSF & PSU - Polyphenylsulfone

- Accessories - filaments

- PELLETS

- Resins

- Brands Filaments and 3D Resins

- PEKK & PEEK

- PE - Polyethylene

- PVDF - Polyvinylidene fluoride

- ESD-Safe

- PACKS

- +3D printers

- +Tailor-made workings and kits

- Gift Cards

- CLEARANCE

- Manufacturers

- DHM online services

- New Products

- Prices Drop

- My Projects

- Blog

- Contact Us

- Help

- Product Details

- Description

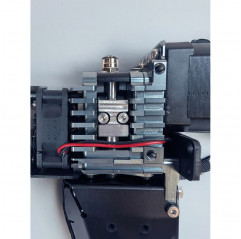

Welcome to a new era of additive manufacturing, where excellence in extrusion technology is combined with savings in time and money. Discover the next generation of 3D printing with the Zephyr extrusion system, which offers one of the highest volumetric flows on the market for 1.75 mm filament.

At the heart of Zephyr is Zephyr's unique MeltCore technology, designed to ensure consistent melt and faster flows, improving overall printing efficiency. The lightweight design, combined with advanced features such as the powerful 140W heater, filament tension adjustment, and dual-socket mechanism, enables Zephyr to deliver unparalleled performance.

By optimizing extrusion efficiency, Zephyr not only saves time but also reduces operating costs, making it an indispensable tool for those looking to maximize productivity and convenience.

Incomparable High-Flow PerformanceAchieve high 3D printing speeds without sacrificing quality

The Zephyr High Flow extruder sets a new standard in 3D printing. With a volumetric flow of 685 grams per hour (154 mm³/s) per 1.75 mm filament, it offers unparalleled efficiency and speed, making it one of the fastest extruders on the market.

With a maximum heating temperature of 450°C, Zephyr™ can handle high-temperature materials such as PEEK and PEI, expanding the range of possible applications and making it a versatile tool for advanced printing needs.

Superior Quality and Performance

Goodbye to extrusion problems

The Zephyr High Flow extruder enhances 3D printing by ensuring consistent extrusion performance. This ensures that the material is fed evenly, producing reliable, high-quality prints. Enjoy superior results without the need for constant adjustments or remakes. Zephyr simplifies the printing process, saving time and increasing productivity.

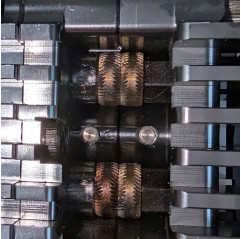

Dual Grip Mechanism

Innovative dual grip technology improves filament traction, reducing slippage and increasing feeding accuracy, critical for consistent extrusion and high print quality.

Filament Tension Adjustment

The filament tension adjustment feature, with nine settings, supports flexible and large filaments, ensuring optimal extrusion for all types of material.

Precise Gear Ratio

With a gear ratio of 3.1:1, the system offers the perfect balance between speed and torque, adapting to a wide range of printing needs.

Powerful Heating System

The 140W heater and PT100 sensor enable precise temperature control and fast heating times, ensuring optimal extrusion conditions for all types of materials.

Perfect Integration

Optimize your 3D printing process

The Zephyr High Flow extruder offers unparalleled adaptability and precision. With its lightweight design, versatile nozzle options, and universal material compatibility, it integrates seamlessly into any printing environment. Whether you're working on detailed prints or high-speed production runs, Zephyr™ adapts to your needs, improving efficiency and performance.

Lightweight Design

Weighing approximately 700 g, the Zephyr system offers exceptional portability for a high capacity extruder, making it ideal for a variety of operating environments without compromising performance.

Versatile Nozzle Options

With nozzles from 0.4mm to 2.5mm, Zephyr is suitable for both detailed prints and high production speeds, providing versatility for various printing tasks.

Universal Material Compatibility

Zephyr is designed to work with all printable materials, including elastomers, high-temperature polymers and standard filaments, making it a versatile choice for any printing project.

Easy Maintenance

Designed with the user experience in mind, Zephyr allows easy access to internal components for maintenance and cleaning, ensuring long-term reliability and consistent performance.

Innovative MeltCore TechnologyAt the heart of Zephyr is the revolutionary MeltCore technology. This ensures consistent melting and faster flows, improving overall printing efficiency. The advanced 140W heater and PT100 sensor provide precise and powerful temperature control, which is critical to achieving high-quality prints.

Technical Information

Parameter Specification Weight ±700 g Dimensions 47.3 mm x 104.1 mm x 123.7 mm Flow (Output Flow)* 685 g/hour 154 mm³/s Nozzle Sizes 0.4 mm, 0.6 mm, 0.9 mm, 1.2 mm, 1.8 mm, 2.5 mm Voltage 24 V DC Maximum Ambient Temperature -10°C ~ 60°C Maximum Operating Temperature Up to 450°C Compatible Material All printable filament materials Diameter 1.75 mm Package Contains: 1 x Zephyr High Flow Extruder - Dyze Design

- Read more

Please visit the links below to explore technical specifications, installation guides, and lots of other useful information.

- https://dyzedesign.com/blog/

- https://dyzedesign.com/2023/03/what-dyze-extruder-is-the-best-for-your-application/

For more information please contact us.

The item you receive may differ in some features from the one pictured, depending on the production batch. Despite this, functionality is maintained.

- Attachments

- Questions(FAQs)

Related articles on blog

- Images