Worldwide express shipping

- My DHM

- +Products

- +Mechanical components

- +Profiles structural and accessories

- +Hardware and Screws

- +Industrial material

- +Robotics and Automation

- Motor driver

- Relays and switches

- Power supplies

- Modules and card expansions

- Fans

- Parts for cards

- Control cards

- Arduino boards

- Integrated computers and development boards

- Spies and warning lights

- Duet 3D

- Arduino compatible

- Optoelectronics

- Passive components

- Thermal management

- Video surveillance

- Sensors

- Batteries and Chargers

- Semiconductors

- PCB Prototyping

- Motors

- Data storage and connectivity

- CNC Machines

- +Electrical equipment

- +Extruder group - 3D printing

- +Print bed - 3D print

- +Filaments and 3D Resins

- PLA

- Special PLA

- Loaded

- PETG

- Co-polyesters

- PP - Polypropylene

- Eraser

- PA - Polyamide

- ASA

- ABS

- Special ABS

- PC - Polycarbonate

- PVA and supports

- HIPS

- SKIN contact

- PEI - Polyetherimide

- PMMA

- PPSF & PSU - Polyphenylsulfone

- Accessories - filaments

- PELLETS

- Resins

- Brands Filaments and 3D Resins

- PEKK & PEEK

- PE - Polyethylene

- PVDF - Polyvinylidene fluoride

- ESD-Safe

- PACKS

- +3D printers

- +Tailor-made workings and kits

- Gift Cards

- CLEARANCE

- Manufacturers

- DHM online services

- New Products

- Prices Drop

- My Projects

- Blog

- Contact Us

- Help

- Product Details

- Description

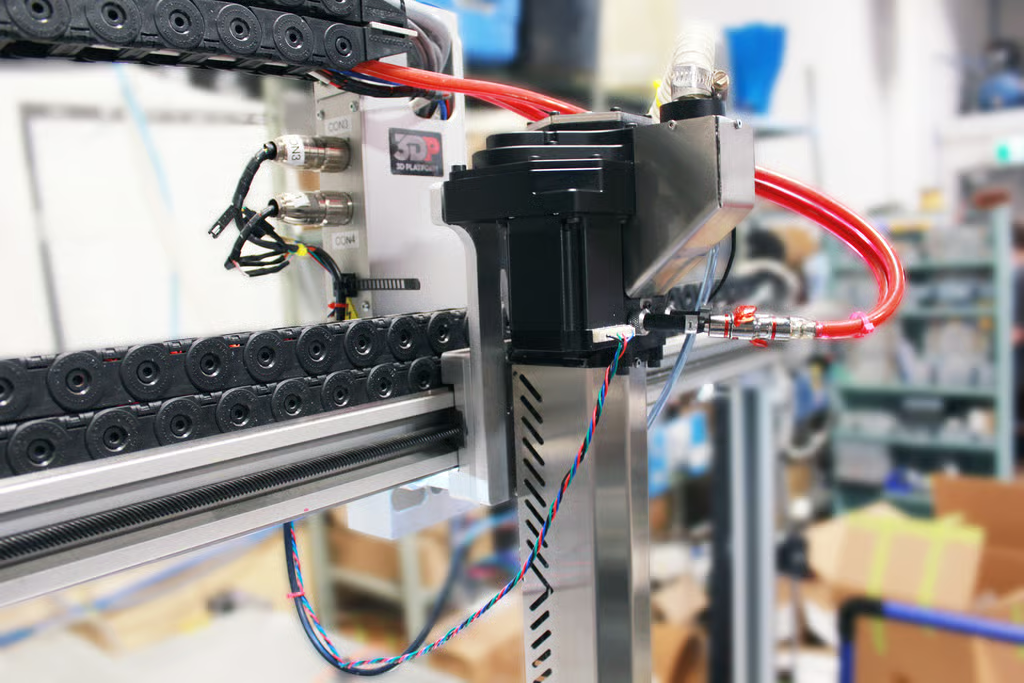

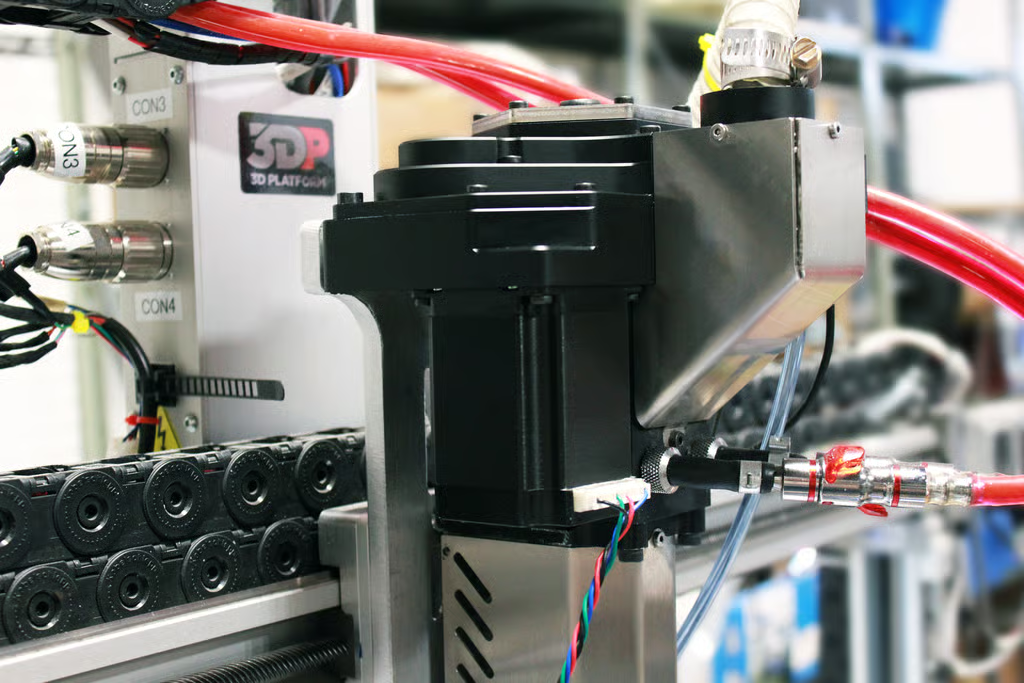

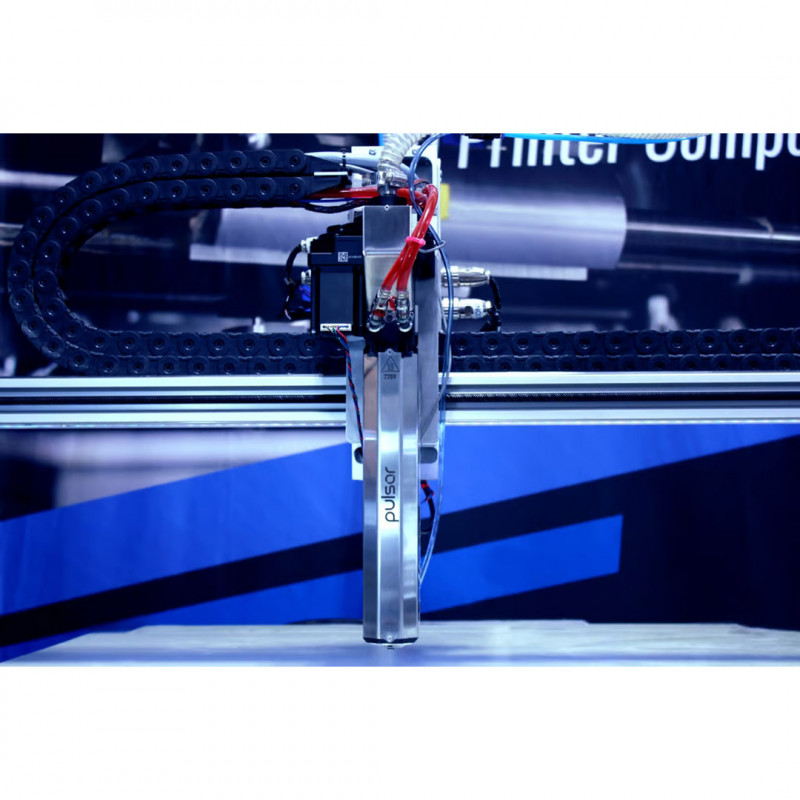

Pulsar is a state-of-the-art, high-throughput, large-scale plastic pellet extruder.

It was designed with one goal in mind: to 3D print parts of one cubic meter and more in the most rapido and cost-effective way possible.

Pulsar is compatible with any large-format 3D printer or even robotic arms and is capable of extruding up to 500 mm³/s (2.5 kg/h) of material.Welcome to the Era of Industrial 3D Printing

Ultra High Flow

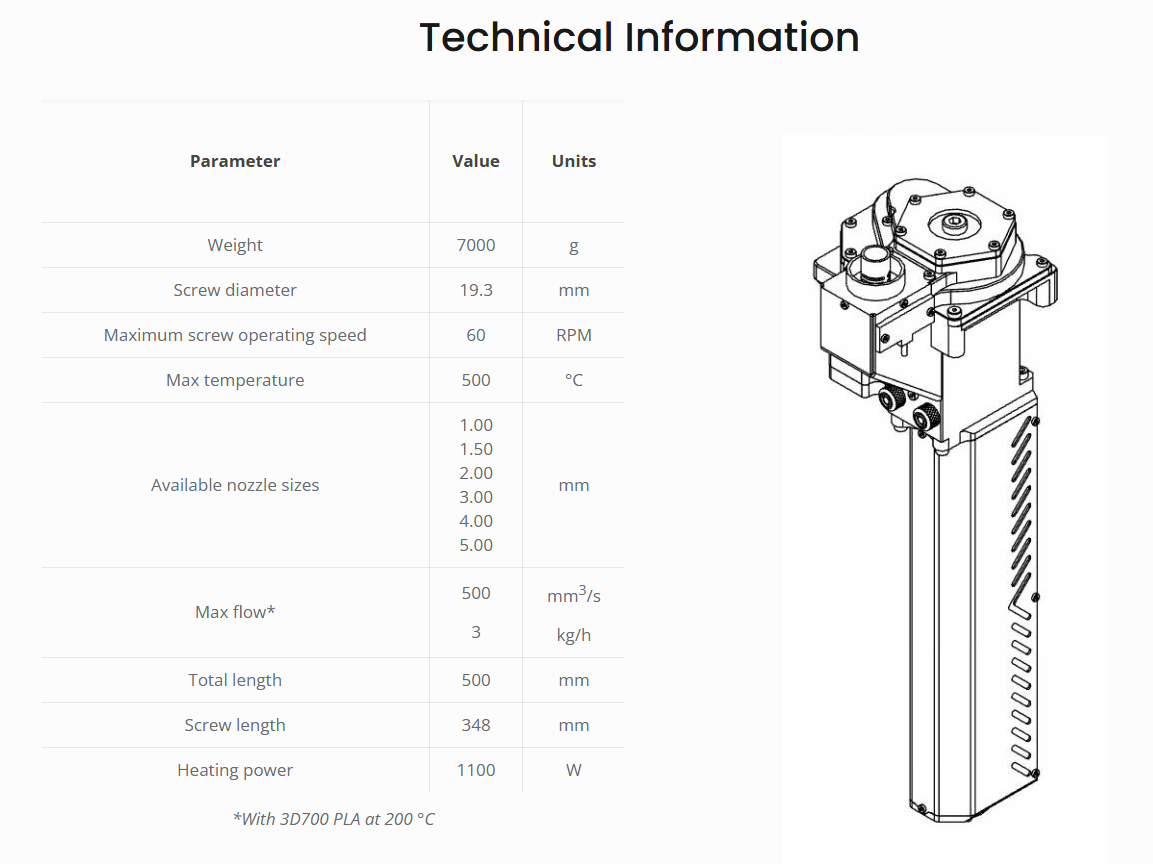

The Pulsar can extrude up to 500 mm³/s (2.5 kg/h). It has the highest flow rate and is one of the fastest portable pellet extruders on the market.

Customized extrusion screw

The screw design is optimized for high-resolution 3D printing.

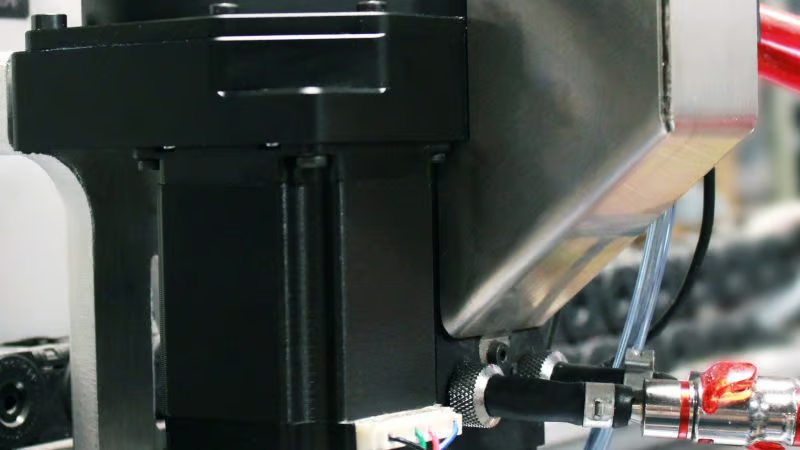

Three-zone heating control

The triple heat zone system ensures that the polymer maintains a constant temperature.

The upper part receives cold pellets and generates more heat to melt them.

The middle zone stabilizes the polymer at a precise temperature.

Finally, the nozzle heater ensures an even flow.

Automatic feeding system

The Pulsar can be equipped with an optional feeding system that detects the level of pellets. Pellets can be supplied from a bulk source.

Multiple nozzles

Compatible with large nozzle sizes from 1.00 mm up to 5.00 mm.

Uniform heating

Spiral heaters wrap around the entire heated cylinder, ensuring uniform temperature all the way to the extrusion end.

Melt zone sensor

Temperature sensors are positioned only 0.50 mm from the melt polymer. Readings are reliable and accurate.

Hardened steel nozzle

Ultra abrasion-resistant steel nozzle prevents changes in nozzle size and height during large prints with abrasive materials.

Powerful NEMA23 motor

NEMA23 motor with gearbox easily handles high flows effortlessly.

Precise temperature control

Three high-precision Class A PT100 sensors ensure accurate measurement. The circuit is designed to achieve maximum resolution between 0°C and 500°C.

Ultra durable

The all-metal chassis is made of aluminum alloy, designed to withstand high stress even under harsh conditions.

Liquid Cooling

The Pulsar is ready for any environmental condition. With powerful heating zones, the liquid cooling circuit keeps the system at a constant temperature.

Anti-oozing mechanism

Because the screw cannot pull back molten plastic, an anti-oozing mechanism ensures clean and defect-free prints.

High-temperature materials: PEEK, Ultem, PSU

Thanks to high-temperature heaters, sensors and extrusion components, it is possible to print up to 500°C.

Heating power 1100 watts

High flow requires a lot of energy. The 1100 W heating system ensures a stable temperature even under high-speed 3D printing conditions.

Non-planar 3D printing

The non-planar heatcore version provides more free space around the nozzle, making it easier to print with non-planar trajectories. It can also be mounted on a robotic arm to increase printing possibilities.

Prints any type of plastic

The Pulsar can print all types of plastic pellets currently produced on the market.

Standard Flexible Support Advanced Engineering Other PLA TPE PVA PC PEEK Metal Powder Filled ABS TPU HIPS PET PEI Wood Filled PETG Carbon Fiber Filled NYLON

Package Contains: 1 x Pulsar Large-Scale Pellet Extruder - Dyze Design

- Read more

Please visit the links below to explore technical specifications, installation guides, and lots of other useful information.

- https://dyzedesign.com/blog/

- https://dyzedesign.com/2023/03/what-dyze-extruder-is-the-best-for-your-application/

- https://dyzedesign.com/2024/05/flow-to-rpm-factor-optimize-your-3d-printing-with-pellet-extruders/

For more information please contact us.

The item you receive may differ in some features from the one pictured, depending on the production batch. Despite this, functionality is maintained.

- Attachments

- Video

- Questions(FAQs)

Related articles on blog

- Images