Pellet 3D printing represents one of the most important innovations for large-scale additive manufacturing. With the Pulsar™ and Pulsar™ Atom extruders, Dyze Design introduces high-performance solutions that combine power, precision, and sustainability.

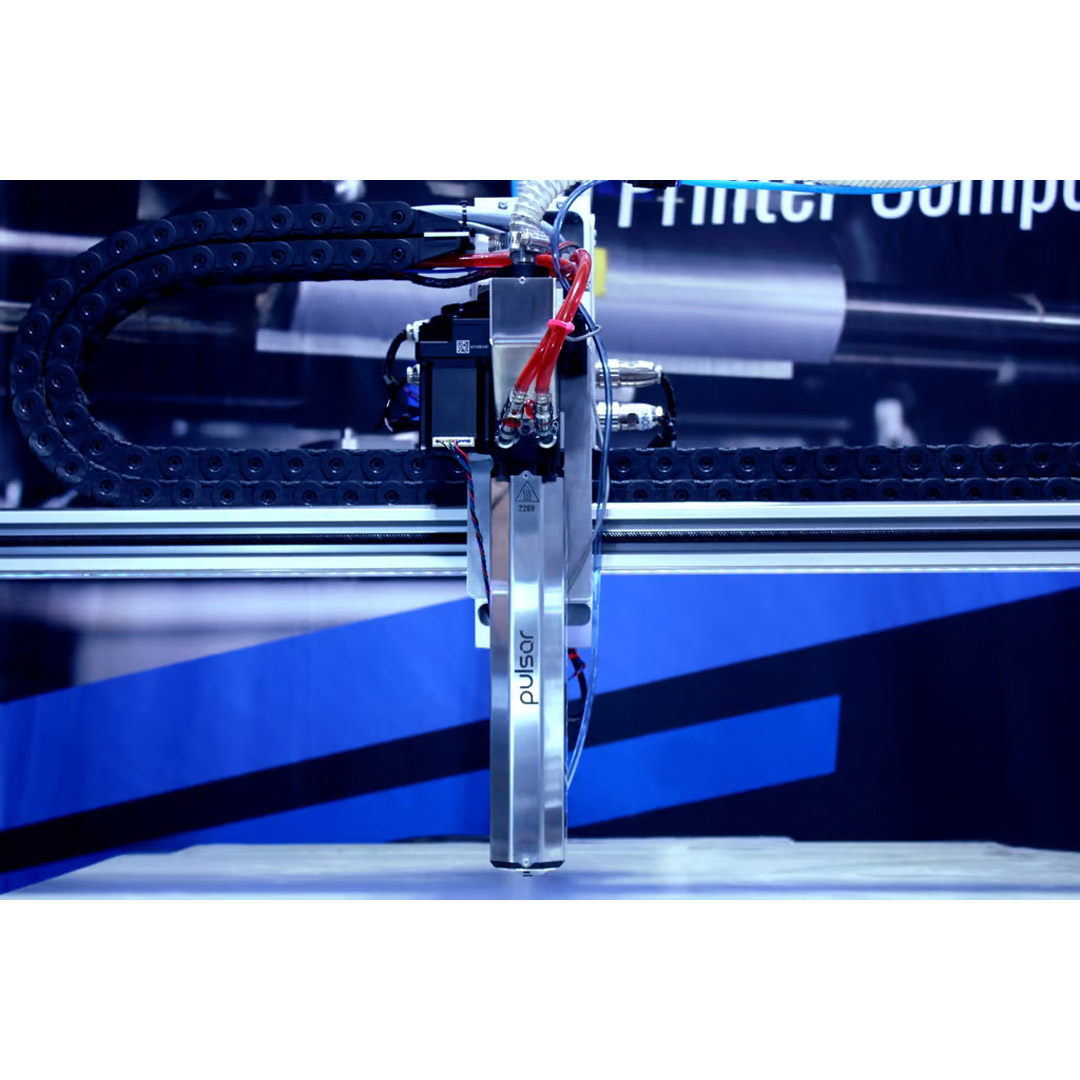

Pulsar™: Power and Productivity for Large Formats

The Pulsar™ Pellet Extruder is designed for industrial applications and large-format 3D printing systems. By handling standard thermoplastic pellets, it drastically reduces material costs and expands the range of printable polymers.

Key Features:

-

Volumetric flow up to 5000 g/h, ideal for high-volume extrusion.

-

Multi-point heating for uniform melting up to 500°C.

-

Precision screw feeder for constant, void-free material feed.

-

Compatibility with high-performance materials, including PEI, PEEK, ABS, PC, and fiber-filled composites.

The Pulsar™ system can be integrated with Cartesian machines, robotic arms, or CNC gantries, providing a robust base for large-scale industrial production.

Pulsar™ Atom: Compact Precision for Advanced 3D Printing

The Pulsar™ Atom is designed for those who want industrial extrusion quality in a more compact format. With a flow rate of up to 1000 g/h (≈234 mm³/s), it ensures speed, thermal control, and flow stability even for complex operations.

Technical Specifications:

-

Maximum temperature 450°C, suitable for technical materials.

-

Optimized compression ratio for uniform pellet melting.

-

Modular design, available in air-cooled or liquid-cooled versions.

-

Universal compatibility with industrial control systems and open-source firmware.

Pulsar™ Atom is the perfect solution for those seeking high productivity in limited spaces while maintaining Dyze Design’s signature quality.

Advantages of Pellet Extrusion

Compared to traditional filament, pellet printing offers significant benefits:

-

Material cost reduction up to 80%.

-

Greater polymer flexibility, including recycled and custom pellets.

-

High printing flows, ideal for large volumes.

-

Reduced environmental impact, thanks to less packaging and reusable pellets.

With Pulsar™ systems, 3D printing becomes more sustainable and cost-efficient.

Applications

Pulsar™ extruders are used across multiple sectors:

-

Automotive and aerospace: technical components in advanced materials.

-

Construction and architecture: large-format structural and decorative elements.

-

R&D: testing new thermoplastic and composite materials.

-

Sustainable production: using recycled pellets to reduce waste.

Conclusion

With Pulsar™ and Pulsar™ Atom, Dyze Design redefines pellet extrusion for 3D printing. Industrial power, precision, and sustainability combine in solutions ready for the future of additive manufacturing. Whether printing large components or exploring innovative materials, the Pulsar series offers maximum productivity and operational flexibility.

Hai bisogno di supporto tecnico?

CREDITS @Dyze Design