The design of fastening components often overlooks an essential aspect: the configuration of the screw clamping.

Unlike the shape of the head, the type of clamping determines how torque is applied and how the screw is driven into the joint. This choice directly affects the performance, safety and durability of the fastener.

The head of the screw is the part where the tightening force is applied. Theengagement (or indentation) engraved on the head indicates the type of tool needed and defines how the torque is transmitted.

Below we look at the main clamping types and their applications.

Slotted Head

Slotted, or "slotted," clamping is the most traditional.

Characterized by a single straight slit on the head, it is used with a flat-blade screwdriver.

It is ideal for manual applications and environments where high torques are not required.

Advantages:

-

Simple to make and use

-

Ideal for frequent assembly and disassembly

Disadvantages:

-

Low torque transmission

-

Tendency to slip during tightening

-

Not suitable for industrial automation

Typical applications: electrical components, light mechanisms, cosmetic finishes.

Phillips Head (Crosshead)

Invented in the 1930s by Henry F. Phillips, this self-centering configuration solves many limitations of the Slotted model.

The Phillips head allows better centering of the screwdriver and more even torque distribution.

Advantages:

-

Easy to align

-

Good efficiency in torque transmission

-

Widespread in electrical and mechanical applications

Disadvantages:

-

Can "cam-out" (slip out of slot) at high torques

-

Not ideal for high torque applications

Typical applications: home appliances, electronic equipment, prefabricated furniture.

Pozidriv head

Similar to the Phillips but with four additional fine slots, the Pozidriv offers a firmer grip and less risk of slippage.

It is often used in conjunction with screws for wood or soft materials where centering accuracy is critical.

Advantages:

-

Increased torque transmission

-

Less tool wear

-

Good self-centering

Typical applications: carpentry, furniture, wood construction.

Hexagonal Head (Allen Drive / Allen)

The internal hexagonal head (also called Allen or Allen wrench) uses a hexagonal wrench to apply torque.

It offers a compact profile, high tightening capacity and good resistance to high torques.

Advantages:

-

High torque transmission

-

No risk of slipping

-

Good for confined environments

Disadvantages:

-

Requires dedicated wrenches

-

Can accumulate dirt in the hex bore

Typical applications: bicycles, machine tools, precision mechanical components.

External Hexagonal Head

In this case the entire head serves as an attachment for a hexagonal wrench or socket.

It is one of the most robust and popular configurations in industry.

Advantages:

-

High torque resistance

-

Easy to assemble even with power tools

-

Ideal for structural fasteners

Typical applications: industrial fasteners, metal structures, heavy machinery.

Torx head (Six-pointed star)

Torx tightening represents one of the most modern developments.

The six-point star shape allows optimal torque transmission and dramatically reduces wear on the fastener and tool.

Advantages:

-

Maximum efficiency in torque transfer

-

No risk of slippage

-

Excellent for automation and mass production

Disadvantages:

-

Needs specific tooling

-

Higher cost than standard footprints

Typical applications: automotive, electronics, wood structures, industrial machinery.

Other Technical Clamping Profiles

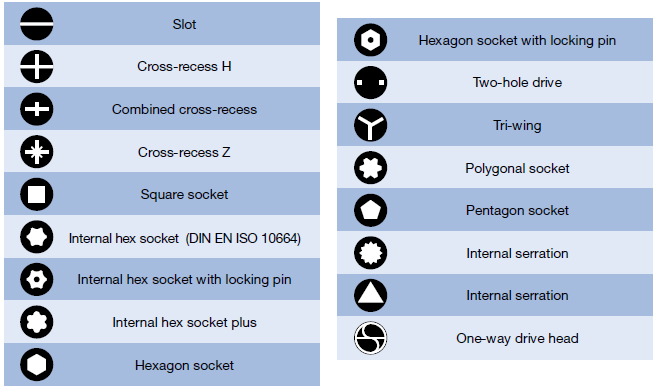

In addition to the most common types such as Slotted, Phillips, Hex and Torx, there are numerous special profiles designed for specific safety, automation or high-precision needs.

These profiles help optimize torque transfer, reduce tool wear and prevent unauthorized disassembly.

Additional clamping types

-

Slot → the classic linear screwdriver blade cut.

-

Cross-recessH → standard Phillips-type cross-recess.

-

Combinedcross-recess → combination of profiles for multiple tools.

-

Cross-recess Z → reinforced variant of the cross-recess profile.

-

Square socket → square socket, used in structural fasteners.

-

Internal hexsocket (DIN EN ISO 10664) → standardized internal hex profile.

-

Internal hex socket with locking pin → variant with tamper-resistant security pin.

-

Internal hex socket plus → optimized profile for high torque transmission.

-

Hexagon socket → classic hexagonal clamping with allen wrench.

-

Hexagon socket with locking pin → security version for industrial applications.

-

Two-hole drive → two radial holes for precision tools.

-

Tri-wing → triple-wing, typical of electronic and aerospace devices.

-

Polygonal socket → high-torque polygonal socket.

-

Pentagon socket → five-sided profile for safety systems.

-

Internalserration → internal serration for special clamping.

-

Internal serration (variant) → reinforced version with more contact teeth.

-

One-way drive head → anti-loosening system: one-way tightening.

Conclusions

Each type of tightening has unique characteristics that affect strength, reliability, and speed of assembly.

From the simplicity of Slotted to the strength of Torx, the choice depends on torque requirements, accessibility, and frequency of maintenance.

For optimal selection, it is important to evaluate:

-

Required tightening torque

-

Material of the component

-

Accessibility and tool type

-

Conditions of use.

Discover the wide range of clamping profiles and screw solutions available at DHM, and find the ideal type for your industrial applications.