Screws represent one of the most versatile and widely used fastening systems in industry. The variety of mechanical requirements, materials, and operating conditions make it essential to know the design principles, relevant standards, and construction characteristics of threaded connections to achieve reliable and durable performance.

Types of Screws and Applicable Standards

Screws can be divided into several categories based on application:

-

Metric screws

-

Self-drilling screws

-

Screws for sheet metal and thin materials

-

Wood screws

Each type meets specific technical requirements and can be regulated by international standards that define dimensions, materials and performance requirements.

The main reference standards include:

-

DIN EN 1591 - Flange joints with circular gaskets

-

VDI 2230 - Calculation of high-stress bolted joints

-

DIN 7500 - Self-drilling screws for metals

-

DVS 2241 - Direct fastenings on plastic materials.

The adoption of recognized standards ensures reliable connections consistent with the safety and quality requirements of different industries.

Design of Threaded Connections

Design Principles

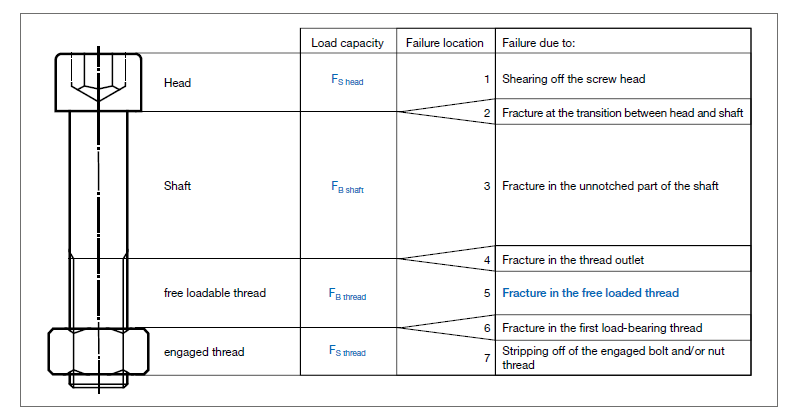

The load carrying capacity of a screw depends on its geometry and the assembly and operating forces. When the screw is stressed beyond the load limit, it tends to deform or break at the point of greatest stress, usually in the threaded area.

Proper design aims to avoid sudden failure by promoting predictable joint behavior and the ability to detect any plastic deformation before failure.

Preload and Friction

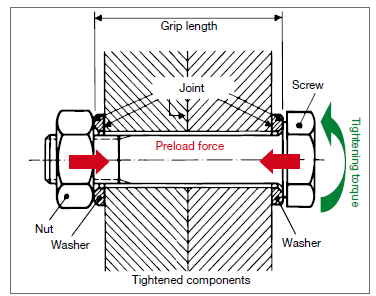

Preload is one of the most important aspects in threaded connections.

During assembly, the tightening moment generates an axial force that causes the screw to elongate and the components to tighten, creating frictional locking between the contact surfaces.

Careful design must consider:

-

The calculation of the optimal preload force.

-

The mechanical strength of the screw and related materials.

-

Operating conditions, such as vibration, thermal variations and external loads.

Preload analysis is critical to ensure that the screw remains stable over time, preventing loosening or failure.

Calculation of Threaded Connections

Analytical Method

In structures with multiple fastening points, the load is distributed unevenly among the screws. Analytical calculation makes it possible to identify the most stressed screw and determine the forces acting on the system in a systematic way.

Finite Element Method (FEM)

The FEM method is used to analyze complex connections and more accurately evaluate local stresses.

It is particularly useful in high-performance applications-such as aerospace or automotive-where detailed analysis of deformation and joint behavior under dynamic loads is required.

Conclusions

The design of threaded connections requires a combination of regulatory knowledge, mechanical analysis and consideration of actual operating conditions.

The use of accurate calculation methods and adherence to international standards ensure joints that are safe, durable and optimized for the specific application.

Proper design reduces maintenance costs, increases safety and improves the overall quality of the final product.

FAQ on Screw Design.

1. What are preloaded threaded connections?

They are joints in which the screw is tightened with a preload force to create frictional locking between surfaces.

2. What regulations govern self-drilling screws?

Self-drilling screws for metals follow DIN 7500, while those for plastics refer to DVS 2241.

3. When is it useful to apply the FEM method?

FEM is suitable for the analysis of complex structures or multiple connections, where the load distribution is not uniform and high calculation accuracy is required.