Screws are essential elements in industrial assembly, but their effectiveness depends largely on the materials used, their mechanical properties and the manufacturing process. In this article, we will explore material certifications, classification of screws by strength, and their application characteristics, with a focus on international standards.

Materials and Test Certificates

The mechanical properties of screws, such as load capacity, depend on both the material used and the manufacturing process. For example, the initial thread characteristics of the material change after processing such as cold forming and heat treatment.

Roles and Responsibilities:

- Manufacturer or Supplier: Selects material that conforms to standard specifications to achieve the required properties in the finished product.

- Designer: Selects the appropriate strength class for the application.

Strength Classes of Steel Screws.

Steel screws are divided into 10 strength classes, indicated by two numbers separated by a dot.

For example, class 5.6 indicates:

- Minimum tensile strength: 5 × 100 N/mm² = 500 N/mm²

- Yield strength limit: 6 × 500 : 10 = 300 N/mm²

Table of Strength Classes

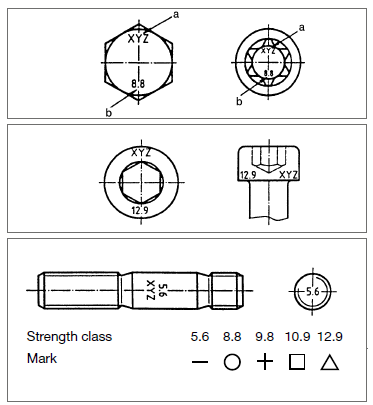

The mechanical properties assigned to strength classes are regulated by DIN EN ISO 898-1, which also establishes mandatory markings:

- Hexagonal screws: Manufacturer's marking and strength class.

- Self-tapping screws: Indicated with specific symbols and a line for the strength class.

- Screws with reduced load capacity: Marked with a leading zero (e.g., 012.9).

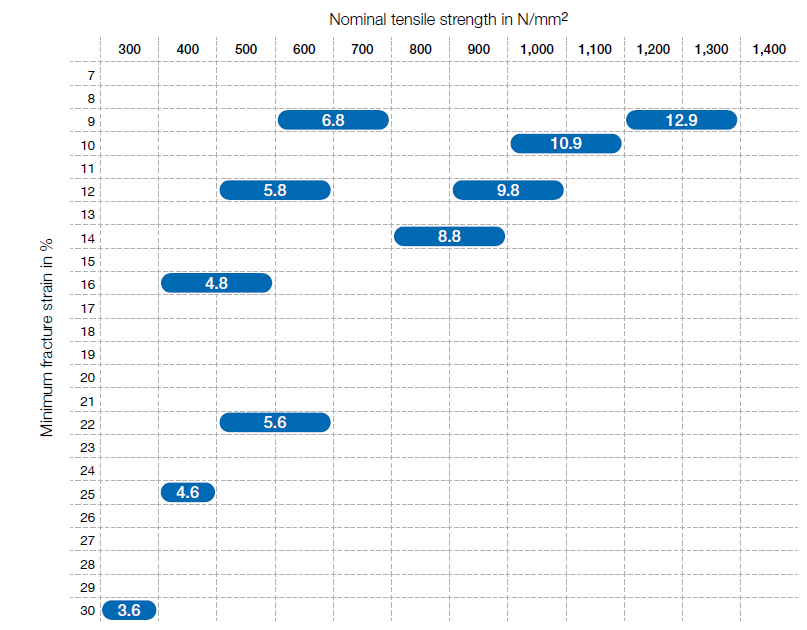

Strength classes (source: DIN EN ISO 898-1)

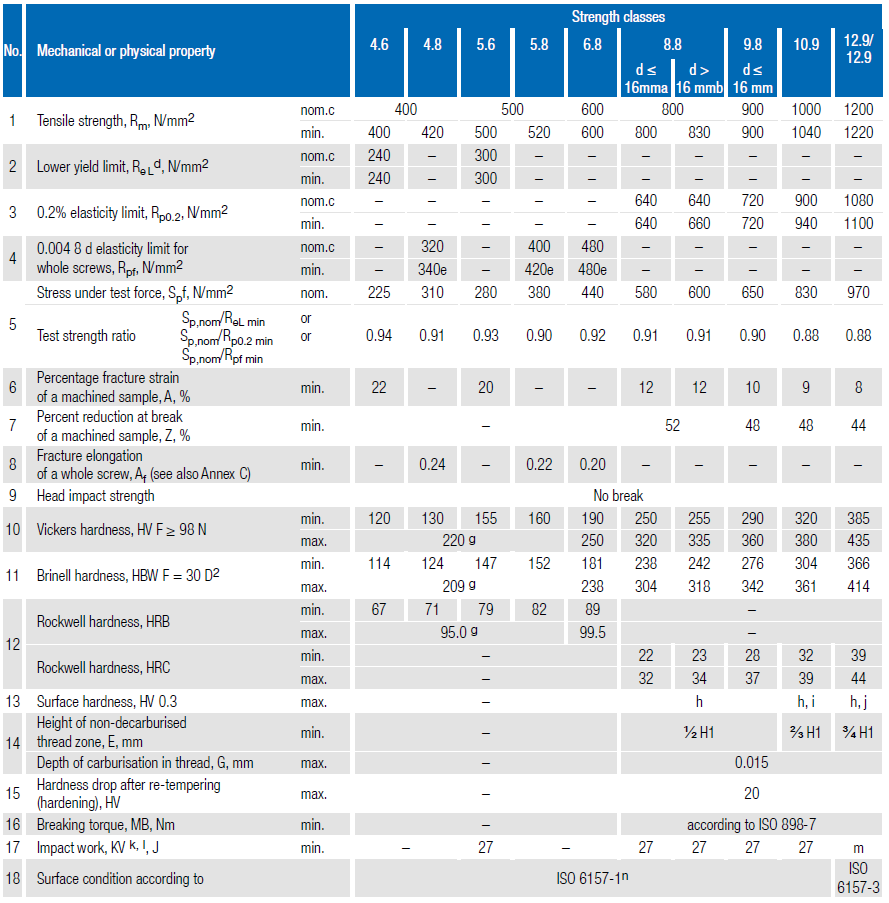

Mechanical and physical characteristics assigned to the strength classes (source: DIN EN ISO 898-1)

Stainless Screws: Classification and Materials

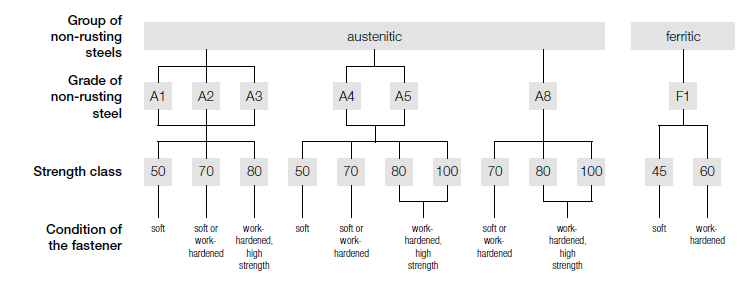

Stainless screws are classified according to DIN EN ISO 3506, which divides screws into steel groups, steel grades and strength classes.

Here is an overview of the main materials:

Austenitic steels (A2, A4, A8)

- Chromium content 15-20% and nickel 5-15%.

- Excellent corrosion resistance and good ductility.

- A2 and A4 are the most common.

- A2: Good corrosion resistance, but not suitable for salt or chlorinated water.

- A4: Superior strength due to molybdenum content (2-3%), partially suitable for marine environments.

- A8: Even higher strength, ideal for salt water, swimming pools and marine environments.

Ferritic Steels (F1)

- Magnetic and cold hardenable.

- Good corrosion resistance in general applications.

Martensitic steels (C1, C2, C3)

- Hardenable by heat treatment.

- Low ductility and lower corrosion resistance than austenitic steels.

Duplex Steels.

- Combination of austenitic and ferritic phases.

- Excellent corrosion resistance and high mechanical strength.

- Magnetic and cold hardenable.

Marking and Classification of Stainless Screws.

Stainless steel screws are classified according to strength classes 50, 70, 80 and 100, where the number represents 1/10th of the minimum tensile strength in N/mm².

Example of Marking:

An A2-70 stainless steel screw:

- A2: Austenitic steel with good corrosion resistance.

- 70: Minimum tensile strength of 700 N/mm².

Naming system for rustproof screws (source: DIN EN ISO 3506-1:2020-08)

Choosing the Right Screw for Your Application

Selecting the right screw depends on many factors, including:

- Operating load: Strength classes ensure the required load capacity.

- Operating environment: A4 or A8 screws are recommended for aggressive or marine environments.

- Corrosion resistance: Duplex and austenitic steels offer superior protection.

Conclusion

Knowledge of strength classes, markings and materials is essential to ensure the safety and reliability of threaded connections. International standards such as DIN EN ISO 898-1 and DIN EN ISO 3506 provide clear guidelines for selecting and designing screws according to application needs.

Investing in the correct selection and use of screws can reduce maintenance costs, improve performance, and ensure long-term safety.

Need technical support or a specific product?

Credits: Bollhoff GmbH