Highlights

- Exploring Current Advances: Discover recent developments in 3D printing of biodegradable polymers.

- Analyze Mechanical Properties: Evaluate the mechanical performance of printed biodegradable polymers.

- Study the Applications: Examine the various applications of biodegradable polymers and their composites in 3D printing.

- Describe Machine Learning Trends: Analyze how machine learning is affecting 3D printing and biodegradable polymers.

- Assess the Overall Potential: Provide an overview to improve the use of biodegradable polymers in 3D printing.

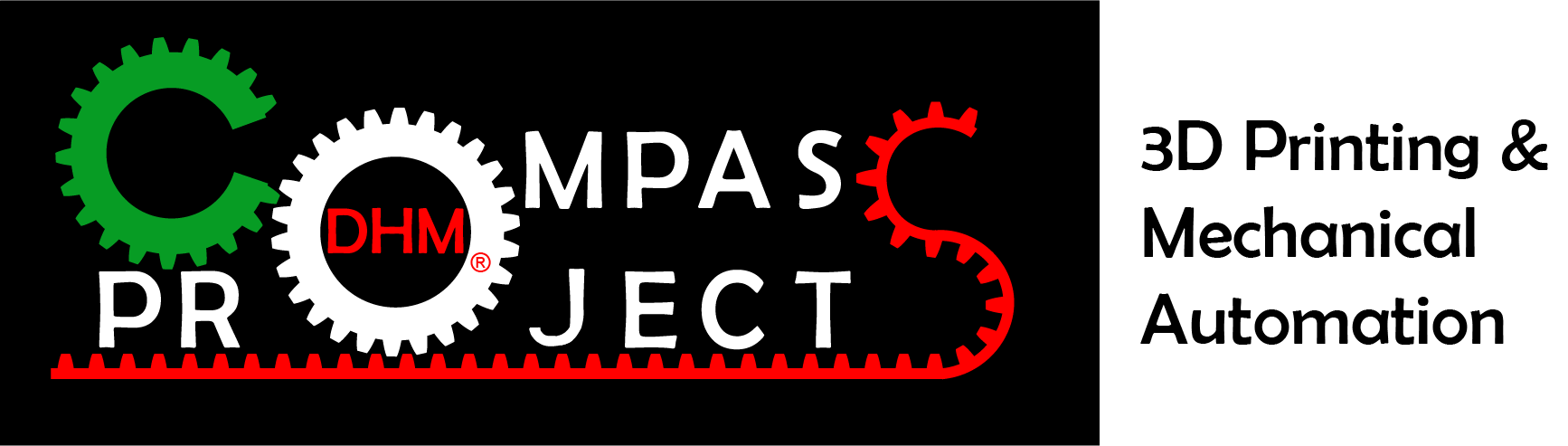

This article explores the use of biodegradable polymers in 3D printing and the involvement of Machine Learning in additive manufacturing (AM), here the aspects we are going to explore:

- Overview of 3D Printing and Machine Learning: Analysis of recent developments and innovations in 3D printing of biodegradable polymers and their composites. Discussion of the role of machine learning in improving manufacturing processes.

- Types of Biodegradable Polymers: Description of various biodegradable polymers, including PLA, PHA and PBS, and their compatibility with 3D printing technologies.

- Preparation and Post-Processing of Materials: Detail of material preparation techniques and design and post-processing strategies specific to biodegradable polymers.

- Practical Applications: Discussion of how these materials are used in areas such as biomedical implants, sustainable packaging and artistic creations.

- Challenges and Continuing Research: Identification of major challenges, such as mechanical properties and recycling issues, and overview of current research to overcome these limitations.

- Future Potential: Assessment of the transformative potential of 3D printing and machine learning with biodegradable polymers and suggestions for future developments in sustainable production and consumption.

In summary, the article provides a comprehensive overview of current technologies and advances in the field, highlighting practical applications and challenges, and suggesting directions for future improvements.

Introduction

3D printing, an additive manufacturing technology, has revolutionized industry in recent decades. Unlike subtractive processes such as milling, additive manufacturing (AM) builds objects by adding material according to software instructions CAD, eliminating the need for physical equipment for new designs. AM offers advantages such as reduced material waste and the ability to produce complex structures directly from digital models.

Role of Machine Learning (AM):

Machine learning is changing the way they design, optimize and create three-dimensional objects, improving the accuracy and efficiency of AM processes. This technology analyzes large data sets to detect trends and make predictions, expanding the possibilities for customization and innovation in materials and geometric complexity.

Materials Used in 3D Printing: Biodegradable Polymers.

Common materials include polymers and polymer-based composites, which can include fillers such as metal nanoparticles and ceramics. Biodegradable polymers, derived from renewable sources, offer a solution for reducing the environmental impact of 3D printing. Examples of biodegradable polymers, such as PLA, PHA, and PBS, hold promise for their excellent printability properties, low toxicity, and biocompatibility. These materials can be obtained from natural resources and biological waste, and they naturally decompose over time, reducing environmental pollution.

Applications of Machine Learning in Biodegradable Polymers.

Machine learning is used to improve materials design, processing and applications by analyzing complex data regarding polymer properties and behavior. Machine learning techniques can optimize material formulations and manufacturing processes, and predict the performance of materials in various environments.

Synergy between 3D Printing and Machine Learning.

Integrating machine learning into 3D printing can transform the design and production of printed parts by improving quality control, process optimization, and material formulation.

Research Gaps and Future Directions

There is a gap in the comprehensive evaluation of the long-term performance and environmental impact of biodegradable polymers in 3D printing. A systematic study is needed to understand the relationship between biodegradable polymers and printing parameters, and to analyze their behavior throughout the lifecycle.

Objectives

This paper aims to examine biodegradable polymers in detail, highlighting their characteristics, applications, environmental impacts and application difficulties, using machine learning techniques to optimize manufacturing processes.

Figure: Graphic Abstract - © https://doi.org/10.1016/j.pmatsci.2024.101336

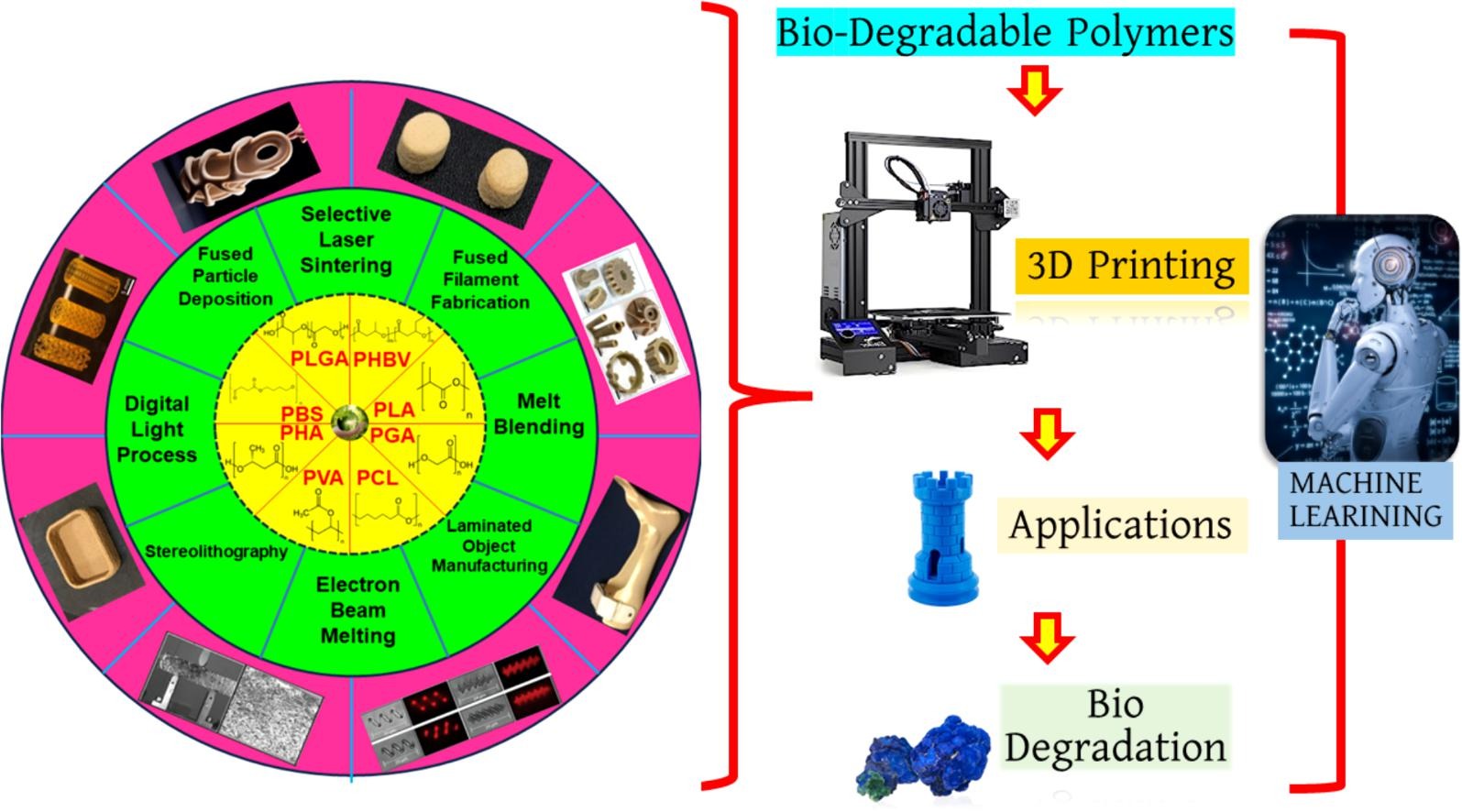

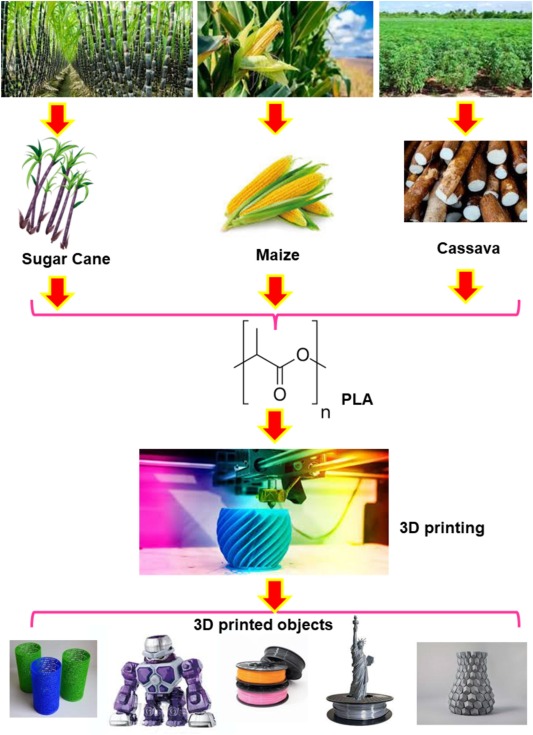

Biodegradable Polymers: Types, Properties and Biodegradation.

Types and Applications: Biodegradable polymers, such as PHA, PLA, PBS and PCL, are environmentally friendly alternatives to traditional plastics, used in packaging, agriculture and medicine. They offer environmental benefits, such as reduced carbon emissions and long-term waste.

Properties and Benefits: These polymers possess good mechanical strength and the ability to biodegrade naturally, contributing to a reduction in plastic pollution.

BiodegradationProcess: Biodegradation occurs through microorganisms and environmental factors, passing through stages of deterioration, biological fragmentation, assimilation and mineralization. The speed of the process depends on the chemical structure of the polymer and environmental conditions.

Issues and Regulations: It is important to avoid greenwashing and ensure that products labeled as biodegradable meet strict standards. Accelerated tests such as the weatherometer are used to simulate environmental conditions and assess the actual biodegradability of materials.

Figure: Internal and external factors affecting polymer biodegradation. © https://doi.org/10.1016/j.pmatsci.2024.101336

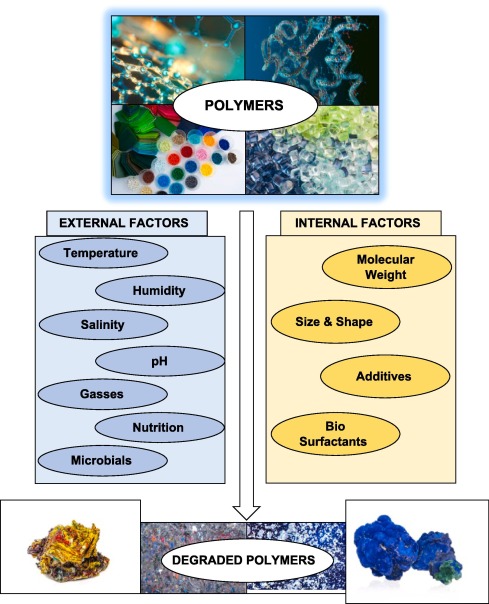

1. PLA (Polylactic Acid)

General Characteristics: PLA is a biopolymer produced from lactic acid monomers, derived from renewable sources such as corn starch, sugar cane, and tapioca root.

Properties: Good mechanical strength, high biodegradability, improved thermal stability and availability.

Production Process:

- Lactic Acid: Produced by fermentation of sugars from renewable sources. Lactic acid polymerization is preferred using lactide, a cyclic dimer, to avoid the production of low-quality PLA.

- Polymerization: The open-cycle polymerization of lactide is preferred because it does not produce water, facilitating the formation of high molecular weight PLA.

Figure: PLA 3D printing process. © https://doi.org/10.1016/j.pmatsci.2024.101336

Cost: More expensive than petroleum-based polymers, mainly due to the cost of fermentation and purification of lactic acid.

Applications and Usage: Used in packaging, medicine, construction, consumer goods, and design.

Properties and Degradability : Mechanical and Thermal Properties: Varies depending on printing parameters. In general, it has good tensile strength and good surface quality, also it is easy to process to can be printed and high printing speeds. It can take up to a year to degrade in domestic composters at 20°C, but can degrade in 12 weeks in warmer environments (>25°C). Degradability in marine environments is difficult to simulate and may vary.

Disposal and Recycling:

- Composting: Effective under industrial conditions with high humidity and temperatures near Tg (60 °C), leading to the formation of water and CO2.

- Mechanical Recycling: Collecting, cleaning and reprocessing PLA can degrade its properties. It is suitable for limited reuses in a closed loop.

- Chemical Recycling: Allows recovery of lactic acid and other useful compounds, with energy advantages over fermentation. Stereochemistry is crucial to maintain the optical purity of the product.

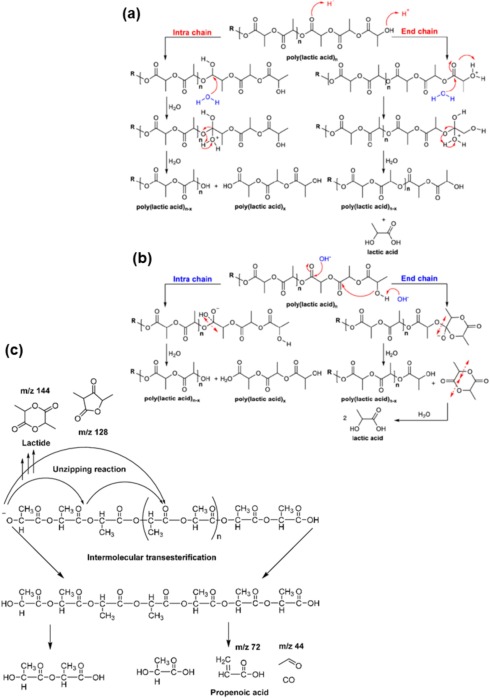

Figure: Mechanism of hydrolysis of PLA in (a) acidic environment and (b) alkaline environment. (c) Thermal degradation of PLA: a simplified mechanism. © https://doi.org/10.1016/j.pmatsci.2024.101336

Problems and Challenges: PLA and PET can be mixed up during recycling, reducing the quality of recycled PET.

Recent Studies: The mechanical and thermal properties of PLA vary widely depending on printing conditions and composition. Degradability and performance in different environments are subject to environmental and process variables.

PLA continues to be a popular choice in the production of environmentally friendly polymers due to its versatile properties and ability to adapt to different applications, especially in the field of 3D printing and biodegradable materials.

2. PHA (Polyhydroxyalkanoates)

Composition: PHAs are aliphatic polyesters produced by bacteria and recognized for their natural biodegradability. There are over 91 distinct components of polyhydroxyalkanoic acids, with a continuous expansion of their varieties.

Classification: PHAs are classified into three groups based on chain length:

- Short chains: 3-5 carbon atoms.

- Medium chains: 6-14 carbon atoms.

- Long chains: 15 carbon atoms or more.

Common Examples: Poly(3-hydroxybutyrate) (PHB) and Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) are the best known and most commercially used.

Production: PHAs are produced by bacteria such as Escherichia coli and Pseudomonas through biosynthesis of specific monomers.

Costs: PHA production is expensive due to high nutrient and energy expenses, constituting more than 75 percent of the final cost. Alternative carbon sources are used to try to reduce costs.

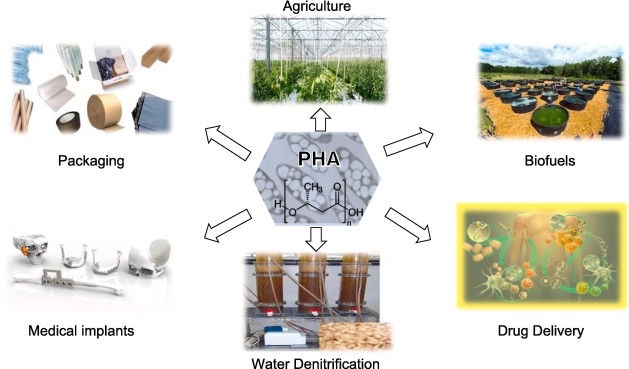

Applications:

- Biomedical Sector: PHAs are used in sutures, cell support films, drug delivery capsules, and scaffolds for tissue regeneration.

- Non-Biomedical Sector: Employed to replace single-use plastics in packaging, plant pots and cutlery, thus reducing plastic waste.

Figure: Applications of 3D printed PHA in different industries. © https://doi.org/10.1016/j.pmatsci.2024.101336

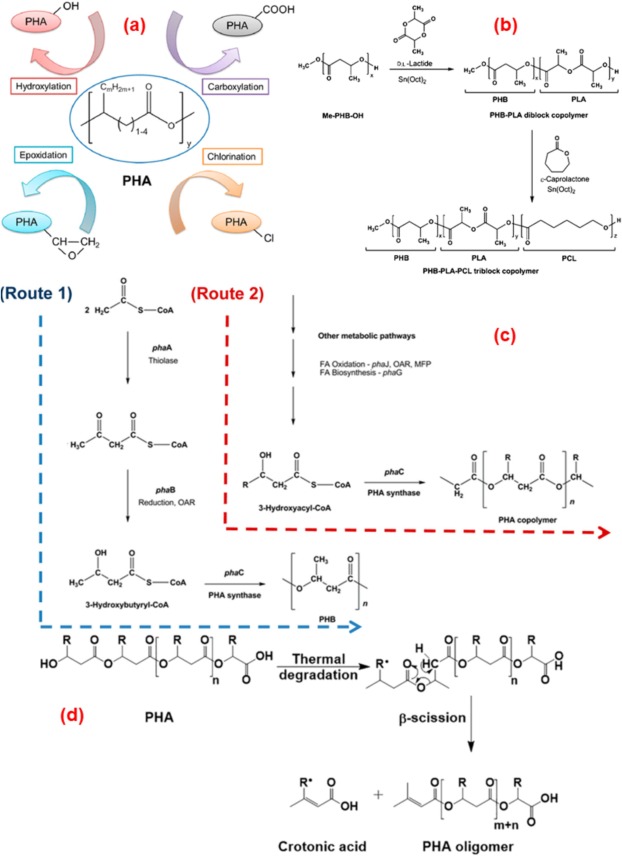

Chemical Modifications:

- Functionalization: PHAs can be modified by carboxylation, hydroxylation, epoxidation and chlorination to suit different applications.

- Copolymerization: PHAs can be combined with other biodegradable polymers to improve their mechanical and functional properties.

Figure: (a) Chemical modifications of PHA. (b) Synthesis of PHB-PLA-PCL triblock copolymer by sequential polymerization with ring opening. (c) Production pathway of PHB copolymer and PHA in terms of biosynthesis. (d) Thermal degradation of PHA by β-scission. © https://doi.org/10.1016/j.pmatsci.2024.101336

3. PCL (Polycaprolactone)

Composition: PCL is a semi-crystalline aliphatic polyester with a relatively low melting point (60°C) and a very low glass transition temperature (-60°C).

Properties: It has low crystallinity and high mobility of chain segments, which contributes to its flexibility and low glass transition temperature.

Production: PCL is produced by polymerization of the cyclic monomer ε-caprolactone by ring-opening polymerization. Various techniques and catalysts are used to control the molecular weight and structure of the polymer.

Cost: Although relatively inexpensive and processable, PCL has a higher cost than some other biopolymers.

Applications:

- Biomedical Sector: Used in prosthetics, sutures, and drug delivery systems due to its biocompatibility and biodegradability.

- Non-Biomedical Sector: Applied in packaging, tissue engineering, and textile fiber manufacturing.

Innovations: PCL is often used in 3D printing to create complex, customized structures.

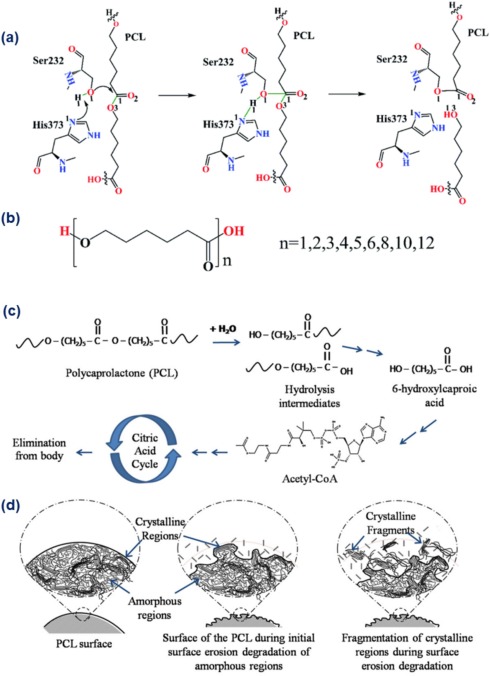

Degradability: PCL degrades through hydrolytic cleavage of its ester bonds. Degradation occurs in two steps: first through nonenzymatic degradation and then through an intracellular process. The presence of NaOH accelerates the degradation of PCL.

Figure: (a) Proposed mechanism for the biodegradation of PCL. (b) PCL is hydrolyzed to produce 6-hydroxy caproic acid and acetyl-CoA, which are subsequently excreted from the body through the citric acid cycle. (c) Diagram showing the possible pathways for crystalline fragmentation. (d) PCL degrades most rapidly in NaOH during a 5-week period. © https://doi.org/10.1016/j.pmatsci.2024.101336

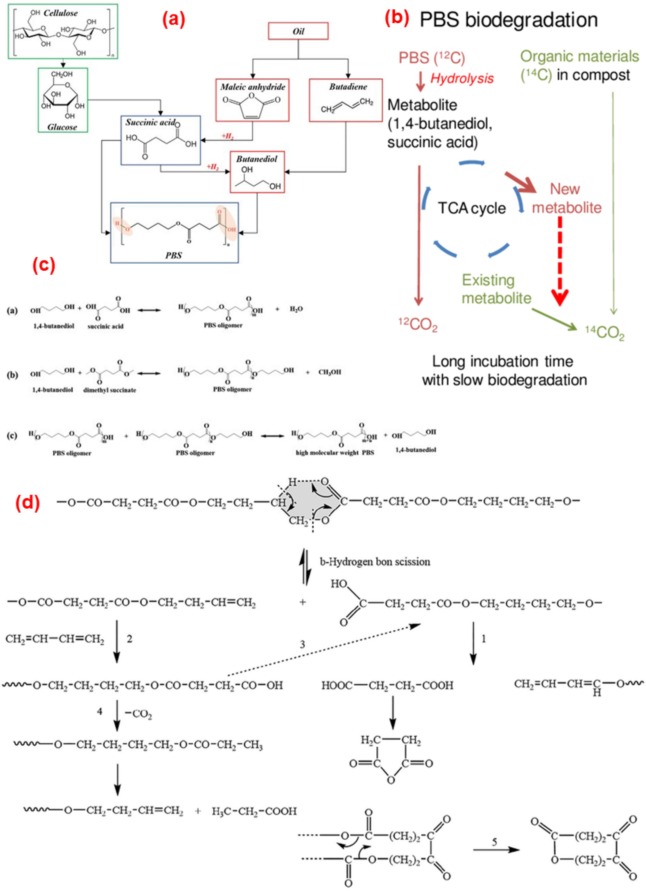

4. PBS (Polybutylene Succinate)

Structure and Characteristics: PBS is a semicrystalline polymer with a versatile structure. Its physicochemical characteristics are similar to those of PET.

The repetitive chemical structure is -[O-(CH2)m-O-CO-(CH2)n-CO]N with m=2 and n=4. PBS polymorphs can be α or β, and the β structure can be formed under stress.

Synthesis: Synthesized by polycondensation of succinic acid (or dimethyl succinate) and 1,4-butanediol. Resources for monomers can be renewable or fossil. Synthesis by renewable resources can be more expensive than petrochemical methods. Some microorganisms are used to produce succinic acid, but have stability problems.

Figure: (a) Flow chart for PBS synthesis from petrochemical and sustainable bio-based feedstocks. (b) Pathways of biodegradation of PBS by microorganisms in regulated compost. (c) Synthesis of PBS. (d) Mechanism of thermal degradation of PBS. © https://doi.org/10.1016/j.pmatsci.2024.101336

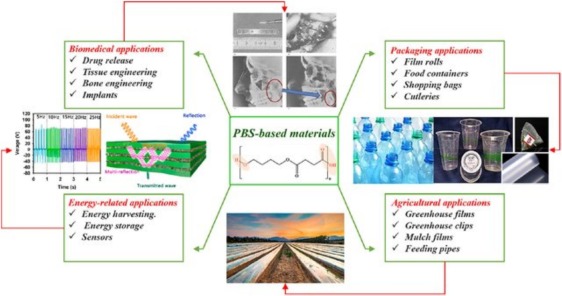

Modification and Applications: Surface modification of PBS by plasma treatments improves its hydrophilicity. Techniques such as chemical polymerization and photochemical grafting further enhance the hydrophilicity of the PBS surface. This material has applications in areas such as packaging, biomedicine, energy and agriculture. In addition, recent advances in 3D printing have expanded the possibilities of using PBS in various applications.

Figure: Applications of PBS in various industries. © https://doi.org/10.1016/j.pmatsci.2024.101336

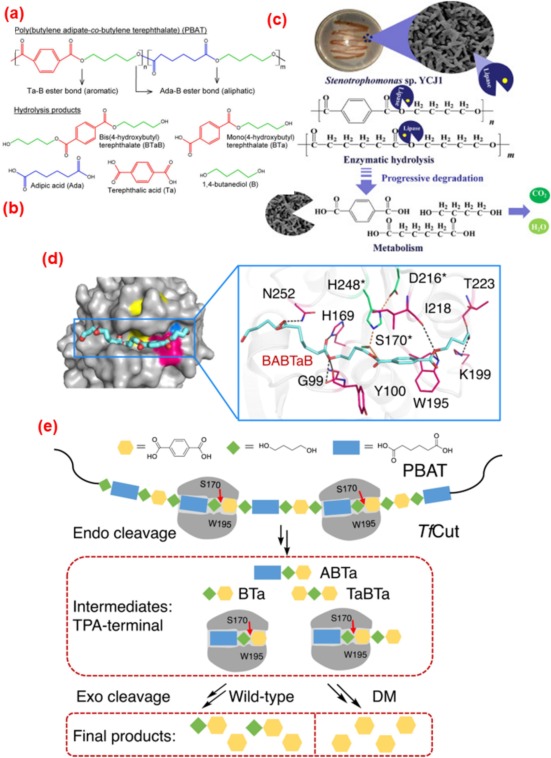

5. PBAT (Polybutylene Adipate-co-Terephthalate)

Synthesis: PBS is created through the polycondensation reaction of BDO, PAT and AA, a process that requires prolonged reaction times and high temperatures, above 190 °C. To facilitate this reaction, organometallic catalysts such as zinc, tin and titanium can be used.

Optimization and Utilization: Nucleating agents, such as talc and silicon oxides, can improve the crystallization behavior of the material. The addition of long-chain branching (LCB) increases melt strength. PBAT films are compostable and are used for various industrial purposes.

Figure: (a) Chemical structure and (b) Enzymatic hydrolysis of PBAT aliphatic-aromatic copolyester. (c) Degradation of PBAT by Streptophomonas. (d) Expected binding of PBAT with TfCut-DM. (e) TfCut-mediated degradation of PBAT. © https://doi.org/10.1016/j.pmatsci.2024.101336

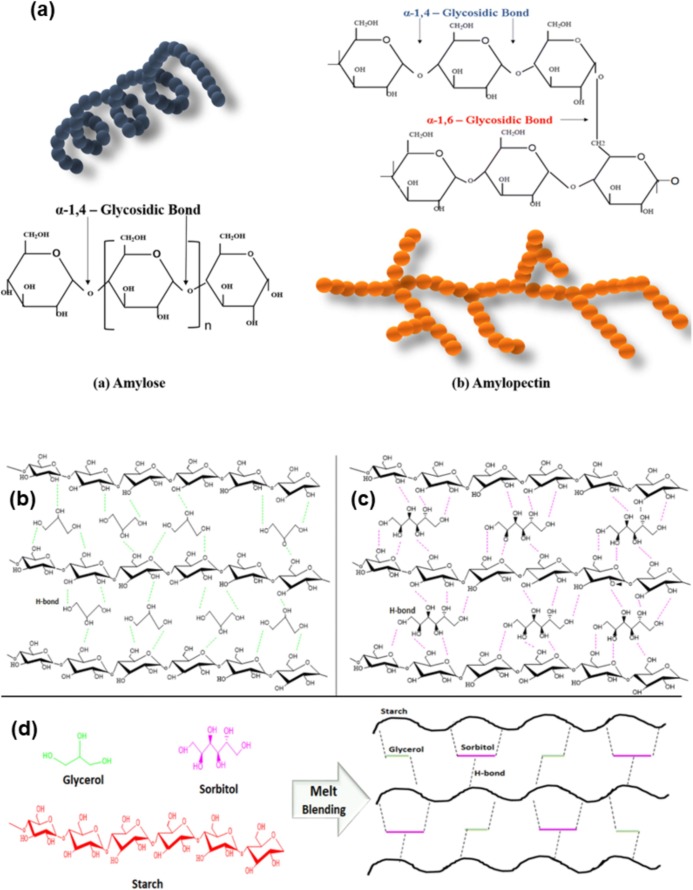

6. Starch-based Polymers.

Characteristics and Processing: Starch is a biodegradable resource, abundant and renewable, composed of linear amylose and branched amylopectin. During thermal processing, starch granules undergo complex modifications, including gelatinization and crystallization.

Applications and Innovations: Starches can be used to produce high-performance bioplastics. Chemical modifications, such as imine polymerization, improve the properties of starch bioplastics. In addition, 3D printing of starch-based polymers offers significant advantages for applications such as scaffolds and hydrogels.

Figure: (a) The molecular formulas for amylose and amylopectin compounds. (b) Diagram showing the hydrogen bonds created when starch is plasticized with (b) glycerol, (c) sorbitol and (d) glycerol/sorbitol after melt mixing. © https://doi.org/10.1016/j.pmatsci.2024.101336

7. Cellulose-based Polymers.

Properties and Origin: Cellulose, derived from wood, plants and agricultural wastes, is an abundant and biodegradable resource. It constitutes the main raw material for papermaking and the pulping process.

3D Printing Applications and Techniques: Cellulose is used in composites, nanocomposites, hydrogels and electronics. It can be combined with other bio-derived polymers to create aerogels and composites suitable for 3D printing. 3D printing of cellulose-based biocomposites takes advantage of its high aspect ratio, availability, and sustainability. These polymers offer a wide range of options for sustainable applications and technological innovations, with growing interest in biodegradable and renewable materials.

3D Printing Technologies for Biodegradable Polymers.

3D printing with biodegradable polymers represents an innovative and sustainable approach in industrial manufacturing.

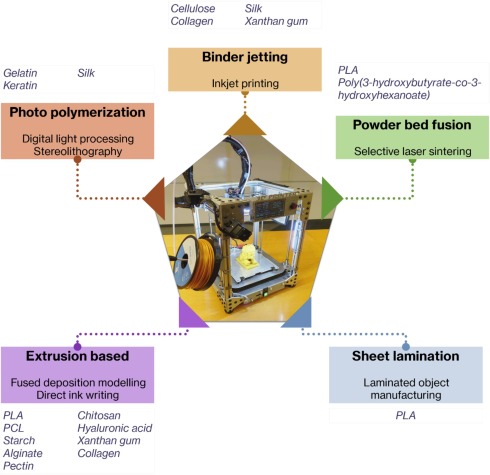

Figure: Additive Manufacturing methods for biodegradable materials. © https://doi.org/10.1016/j.pmatsci.2024.101336

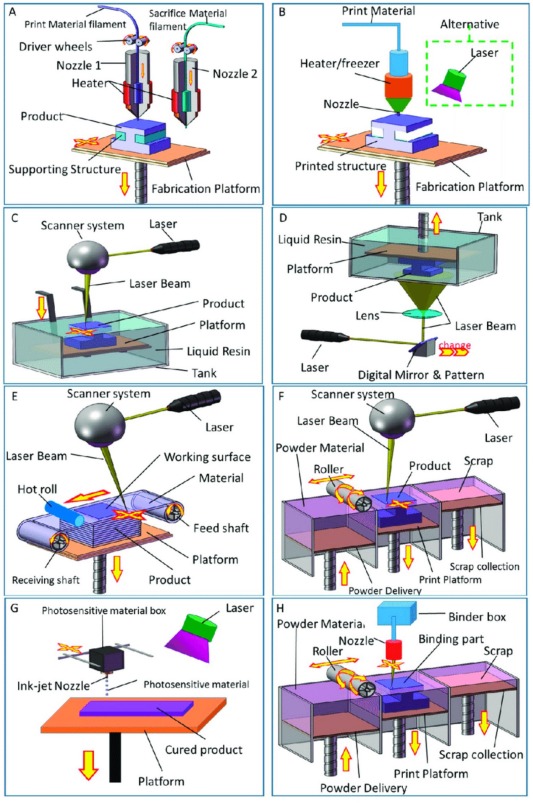

Figure: 3D printing technologies. (A) FDM; (B) DIW; (C) SLA; (D) DLP; (E) Laminating (LOM); (F) SLS and Selective Laser Melting (SLM); (G) Photopolymer Jet (PolyJet); (H) Binder Jet (BJ). © https://doi.org/10.1016/j.pmatsci.2024.101336

Here are the main points:

- Sources of Materials:

- Biodegradable Polymers: Biodegradable polymers are typically obtained from natural sources such as cornstarch, algae, and sugarcane.

- Environmental Impact: These materials offer a solution to the plastic waste problem, degrading over time and thus reducing long-term environmental pollution.

Technological Benefits.

- Customizable Manufacturing: 3D printing allows the creation of complex, custom-made three-dimensional structures, enabling the creation of highly customized products.

- Applications: Biodegradable polymers can be used in a wide range of products, including packaging materials and medical implants.

Sustainability

- Alignment with Circular Economy: The use of biodegradable polymers in 3D printing supports sustainability goals by promoting a circular economy that minimizes waste and optimizes resource use.

- Reduced Environmental Impact: As these materials degrade naturally, they contribute to the reduction of plastic waste, offering an environmentally friendly solution to the problem of environmental pollution.

Future Implications.

- Innovation in Manufacturing: The integration of biodegradable materials into 3D printing technology is a significant step toward more sustainable manufacturing practices, reducing the environmental impact of industrial processes.

- Future Developments: Advances in this field are expected to improve the versatility and effectiveness of biodegradable 3D printed products, paving the way for new applications and innovative solutions in the bioplastics industry.

Biodegradable Polymers: Composites, Blends and Hybrid Materials.

In the field of 3D printed biodegradable polymers, composites, blends and hybrid materials are revolutionizing sustainable manufacturing.

Biodegradable Composites

Biodegradable composites represent an innovative combination of natural fibers or nanoparticles with biodegradable polymers. These materials offer significant advantages, such as superior strength and durability compared to pure biodegradable polymers, without compromising their ecological characteristics.

Due to their versatility, biodegradable composites have applications in various industries, such as consumer products, aerospace and construction. The ability to control the composition of these materials allows for tailored solutions that optimize the balance between sustainability and performance.

For example, the use of PLA combined with poplar wood can improve the torque of the material, although it may have some morphological imperfections. Similarly, PCL enriched with cocoa shells increases Young's modulus and improves crystallization temperature, thus offering superior performance compared to traditional materials.

Biodegradable Polymer Blends.

Biodegradable polymer blends are an innovative strategy that combines different biodegradable polymers to create materials with specific and optimized properties. These blends offer the ability to customize material characteristics by balancing biodegradability, strength and other desirable properties.

Because of their versatility, such blends find application in a wide range of industries. They are particularly useful for flexible packaging, agricultural applications, and medical devices, where combining sustainability and tailored performance is critical.

Hybrid Materials

Hybrid materials represent an innovative combination of biodegradable polymers with non-polymeric materials, such as metals or ceramics. This synergy allows for the distinctive advantages of non-polymeric materials, such as electrical conductivity or heat resistance, without sacrificing the ecological benefits of biodegradable polymers.

These materials find applications in a variety of areas because of their ability to combine high performance and sustainability. They are particularly suitable for lightweight structural components, sustainable medical implants, and environmentally friendly electronic components, where the combination of advanced properties and environmental friendliness is crucial.

Sustainable innovation is at the heart of future developments in the field of biodegradable materials. Continued research and development promises a greener future, with significant advances in the production of biodegradable materials by 3D printing. This technology not only optimizes manufacturing, but also contributes to waste reduction and resource efficiency.

Meanwhile, the evolution of composites, blends and hybrid materials is opening up new possibilities in the design and production of sustainable materials. These developments are driving the industry toward ever greener innovation, enabling solutions that combine advanced performance with reduced environmental impacts. With each step forward, we move closer to a future where sustainability and technology are seamlessly integrated.

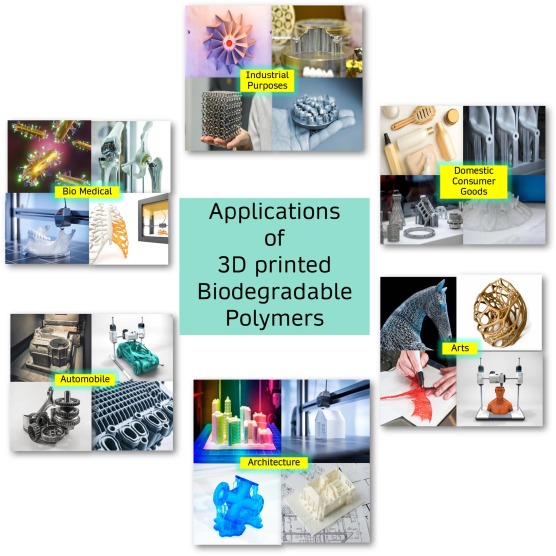

Applications of 3D Printed Biodegradable Polymers.

3D printable biodegradable polymers represent one of the most promising technological innovations in the field of sustainable materials. These polymers not only offer environmentally friendly solutions for various industries, but also revolutionize the way we address environmental and industrial challenges. Below we will explore the main applications of these polymers in the medical, packaging, automotive, aerospace, art, and architectural sectors.

Figure: Applications of 3D printed biodegradable polymers. © https://doi.org/10.1016/j.pmatsci.2024.101336

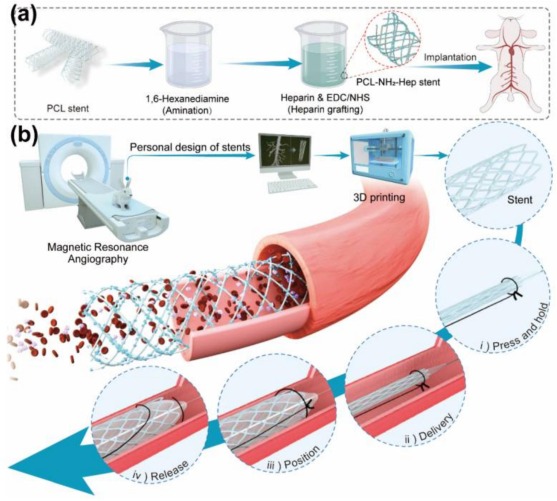

1. Medical Applications of 3D Printed Biodegradable Polymers.

3D printing of biodegradable polymers is revolutionizing the design and manufacture of medical equipment. This approach allows for customized implants and devices that are absorbed by the body without the need for subsequent interventions.

Custom Implants and Devices

With 3D printing, it is possible to create highly customized implants and medical components, such as prosthetic limbs and surgical guides, greatly improving care and outcomes for patients.

Ongoing Studies and Innovations

Researchers are exploring several applications of biodegradable polymers, including:

- Drug delivery devices.

- Tissue regeneration, such as tissues and organs.

- Models for surgical planning.

Practical Examples.

- Mandibular Model in PDLLA: Made by deposition casting (FDM), used for simulations and surgeries.

- Biomedical Stents: Equipped with wireless pressure sensors, designed for blood pressure monitoring.

Innovations in Materials.

- Porous PCL: Created using stearic acid as a porogen, improving biocompatibility for tissue engineering applications.

- BD-TENG: Biodegradable triboelectric nanogenerator capable of generating energy through movement and biodegradable in about 40 days.

- e-Skin Biodegradable and Antibacterial: Developed using nanofibers, this material can monitor mobility and physiological signals in real time.

Figure: Diagrammatic representation of the stent placement and preparation procedure in heparinized PCL. (a) Procedure of modification of heparinization of the stent in PCL. (b) Schematic representation of how magnetic resonance imaging (MRI) guides the 3D production of biodegradable, anticoagulable and customized coronary stents. © https://doi.org/10.1016/j.pmatsci.2024.101336

2. Applications of 3D Printed Biodegradable Polymers in Packaging.

3D-printable biodegradable polymers are changing the packaging landscape by addressing the environmental problems associated with the use of traditional plastics.

Sustainable Substitute to Plastic

These materials offer an environmentally friendly alternative to single-use plastics, which often end up in landfills and oceans, causing pollution and damage to ecosystems.

Custom Design

3D printing enables the creation of complex, customized packaging solutions that are both biodegradable and resource efficient.

Economical and Environmentally Friendly Materials

Biodegradable polymers are often made from renewable resources such as cellulose and corn or potato starch, reducing the carbon footprint of the packaging industry.

Organic Decomposition

These materials naturally degrade upon disposal, decreasing long-term environmental impact and reducing pressure on landfills.

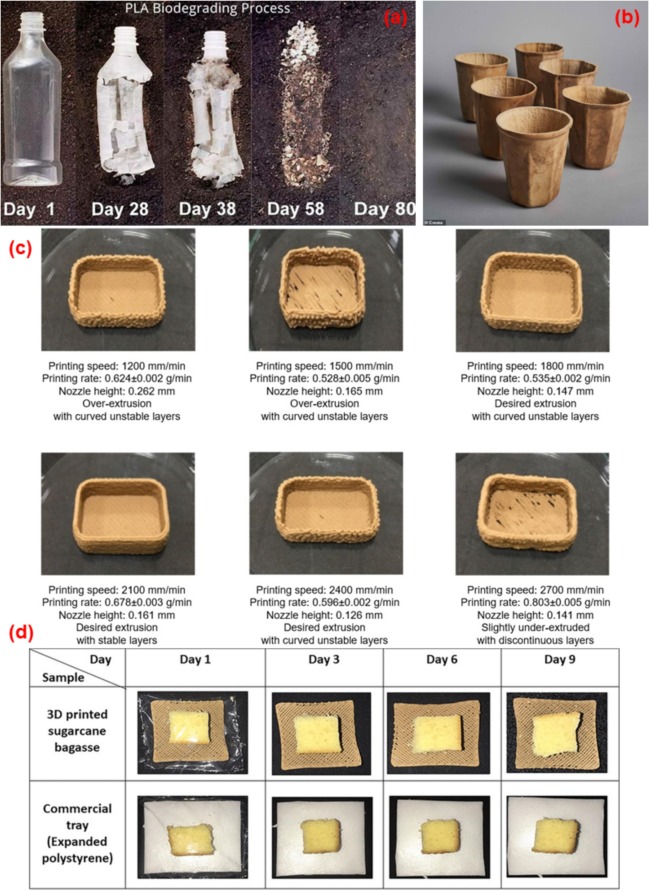

Figure: (a) Biodegradable process of 3D printed PLA bottles. (b) 3D printed biodegradable cups made from fruit waste. (c) 3D printed food wrappers made from ground rice shells and 1% guar gum, using a nozzle diameter of 0.82 mm at motor speed of 300 rpm and pressure of 4 bar. (d) The tray and sugarcane bagasse produced with 3D technology to store the English cake for nine days. © https://doi.org/10.1016/j.pmatsci.2024.101336

3. Applications of 3D Printed Biodegradable Polymers in the Automotive and Aerospace Industry.

Biodegradable nanocomposites are gaining attention in the automotive and aerospace sectors because of their environmentally friendly properties and relatively low cost compared to petroleum-based polymers.

Advantages of PLA Nanocomposites

Polylactic acid (PLA)-based nanocomposites offer high mechanical strength and processability, making them ideal for automotive and aerospace applications.

Innovations in 3D Printing

The use of 3D printable biodegradable polymers in the automotive and aerospace sectors introduces new possibilities for sustainable innovation. The benefits of 3D printing combine with the ecological characteristics of the materials to offer advanced solutions.

Specific Applications.

Automotive Interior: Components such as interior liners and air filter boxes made with high-temperature PLA composites, demonstrating improvements in hydrolysis, heat, scratch, and UV resistance.

4. Applications of 3D Printed Biodegradable Polymers in Art and Design.

3D printable biodegradable polymers offer a sustainable and versatile medium for art and design, addressing the need to reduce plastic waste generated by consumer products.

Properties

These polymers offer wear resistance, high mechanical strength and an evenly distributed polymer matrix, making them ideal for the production of monuments, toys and artwork.

Benefits of 3D Printing

3D printing enables the production of products with dimensional accuracy and reduced production time, attracting customers through the speed and appearance of the products.

Example

Blend of PGA/PBAT: Used to create 3D printing filaments, these biodegradable polymers show excellent mechanical and thermal performance, with comparable test results between printed and FDM-printed samples (Fused Deposition Modeling).

Figure: (a) D-surface TPMS structures with uniform and radially graded pore topologies in geometric models, 3D printed objects and CT reconstruction images. (b) 3D printed GROWLAY biodegradable filament. (d) 3D printed biomass waste PLA chair and Conifer, made of wood-filled PLA. (e) 3D printed biodegradable footwear. (f) Sustainable statues from 3D printed PLA. (g) 3D printed metal and ceramic products from a green polymer-based binder system. © https://doi.org/10.1016/j.pmatsci.2024.101336

5. Applications of 3D Printed Biodegradable Polymers in Architecture and Construction.

3D printing with biodegradable polymers holds significant promise for the construction industry, offering environmental sustainability and design flexibility.

Renewable Materials

Polymers such as PLA (polylactic acid) and PHA (polyhydroxyalkanoates), derived from renewable resources, naturally decompose over time, reducing the long-term environmental impact of construction.

Design and Manufacturing

3D printing technology enables the creation of complex, customized architectural components, reducing waste and optimizing the construction process. This approach helps minimize carbon footprint and material waste.

Applications of 3D-printable biodegradable polymers offer significant benefits in many areas, from medical to packaging, automotive to art and architecture. These innovations not only improve efficiency and sustainability, but also contribute to a more responsible and green future. As technology and research advance, we are likely to see further developments and applications that can address the environmental and industrial challenges of our time.

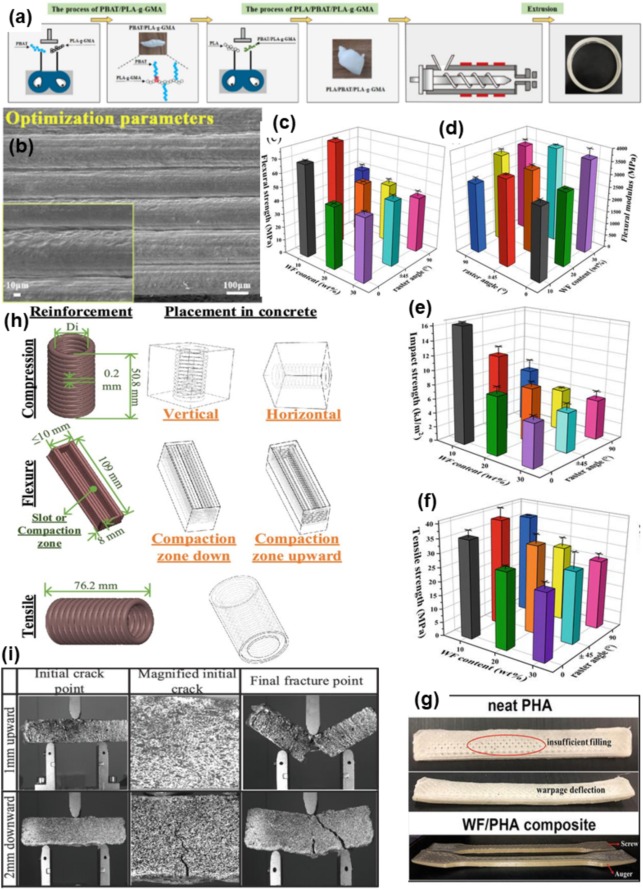

Figure: (a) Creation of highly effective and biodegradable 3D printing filaments, with scanning electron microscope (SEM) photos of samples optimized for 3D printing. (b) Mechanical properties of WF/PHA composites printed with varying concentrations of WF and raster angles: (c) Flexural strength, (d) Flexural modulus, (e) Impact strength, and (f) Tensile strength. (g) Printing defects in PHA products and WF/PHA composites produced with augers and micro screws. (h) Placement of PLA reinforcements in a cement composite specimen and their orientation during 3D printing. (i) In situ analysis of 3D printed PLA flexural specimens for cement reinforcement. © https://doi.org/10.1016/j.pmatsci.2024.101336

Sustainability and Biodegradable Polymers.

Sustainability is a fundamental principle to ensure that our actions today do not compromise the possibilities of future generations. This concept is based on three main pillars: environmental protection, social welfare and economic success. However, addressing sustainability challenges requires a balance between environmental protection, resource management, and economic and social development.

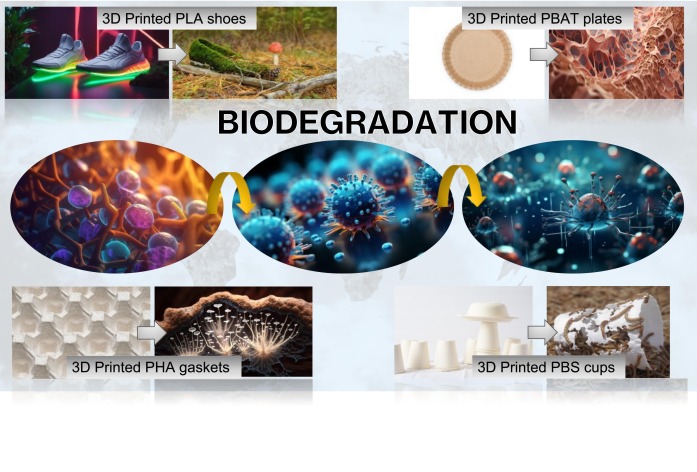

Figure: Biodegradation of biodegradable polymer applications. © https://doi.org/10.1016/j.pmatsci.2024.101336

Problems of Traditional Plastics

Traditional plastics, unfortunately, have a significant environmental impact. Because they are extremely resistant to decomposition, these materials occupy large spaces in landfills and contribute to environmental pollution. Their production requires substantial resources, and although recycling can partially mitigate this problem, it brings additional challenges. In fact, the recycling process can consume additional resources and generate harmful gases.

Biodegradable Polymers

Biodegradable polymers represent a promising solution. These materials are designed to decompose easily through the action of microorganisms, transforming into natural components. However, it is important to note that not all polymers derived from biomass are biodegradable. Their ability to degrade depends on environmental conditions and their chemical composition.

The advantages of biodegradable polymers are obvious: they reduce the load on landfills and greenhouse gas emissions, thus contributing to decreased environmental pollution and more efficient waste management.

Biodegradable Polymers and Renewable Resources

Biodegradable polymers can be produced from renewable resources, such as plants, or from nonrenewable sources, such as petroleum products. Of the two, natural polymers are generally preferred for their inherent sustainability. However, synthetic biodegradable polymers, although derived from nonrenewable materials, also offer significant benefits if managed properly.

Principles of Sustainability in Polymer Manufacturing.

In the production of biodegradable polymers, it is essential to consider the Triple Bottom Line (TBL) principle, which evaluates social, economic and environmental performance. Balancing environmental and social needs with economic goals is crucial to ensure a sustainable future.

Sustainability Goals.

To achieve true sustainability, we must control the use of nonrenewable resources and reduce environmental impacts. At the same time, it is critical to ensure that sustainable development respects rights and promotes social justice.

The adoption of biodegradable polymers and the promotion of sustainability require concerted efforts and a holistic view. Only then can we aspire to a future where resources are responsibly managed and the environment protected for generations to come.

Machine Learning in 3D Printing and Biodegradable Polymers.

Machine learning is emerging as a transformative force in the research and development of biodegradable polymers, opening new frontiers in the field of sustainable materials and 3D printing.

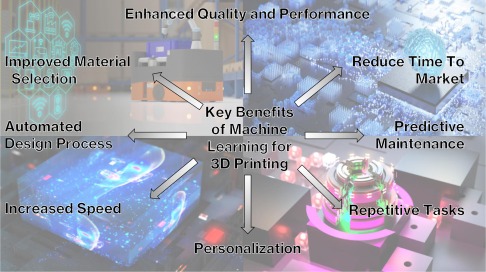

Figure: Benefits of machine learning for additive manufacturing (AM) processes. © https://doi.org/10.1016/j.pmatsci.2024.101336

Figure: Benefits of machine learning for additive manufacturing (AM) processes. © https://doi.org/10.1016/j.pmatsci.2024.101336

Innovation with Machine Learning

A major benefit of using machine learning is its ability to accelerate the discovery of new biomaterials and improve polymer manufacturing processes. Through predictive models and advanced optimization techniques, machine learning can quickly identify optimal material combinations and manufacturing conditions, reducing the time and costs associated with synthesizing and designing new polymers.

Time and Cost Reduction

The adoption of advanced techniques such as combinatorial design and high experimental throughput, supported by machine learning, is revolutionizing the industry. These techniques enable faster and cheaper design and synthesis of polymers, optimizing resources and accelerating innovation. By integrating machine learning into polymer design and additive manufacturing, the performance and sustainability of materials can be significantly improved.

Machine Learning and Biodegradable Polymers

Machine learning is making profound changes in biodegradable polymer research, revolutionizing the way we discover and optimize these materials. With this technology, crucial properties such as crystallinity and melting temperature of polymers can be predicted, overcoming the limitations of traditional methods.

Advantages Over Traditional Methods

Machine learning offers numerous advantages over traditional methods. It significantly reduces the time and resources required for materials testing and synthesis, enabling more rapido and effective development. This technology also facilitates the adaptation and development of new materials with greater accuracy and speed.

Applications in Biodegradable Polymers

In the design and optimization of biodegradable polymers, machine learning is used to analyze and predict material properties based on different combinations and compositions. Advanced software and recent studies show how machine learning can improve 3D printing of biodegradable polymers and other applications, opening up new opportunities for innovation.

Examples and Recent Studies

Recent technological developments have led to the creation of software specifically for 3D printing of biodegradable polymers. Recent studies highlight the effectiveness of machine learning in the design and optimization of these materials, with promising results showing how this technology can revolutionize the field.

The integration of machine learning into the design and production of biodegradable polymers is revolutionizing the field. This technology improves efficiency in materials research and development, offering advanced tools for more precise and sustainable design. The future of 3D printing and biodegradable materials is therefore intrinsically linked to these technological innovations.

Challenges and Future Directions in 3D Printing Biodegradable Polymers

3D printing of biodegradable polymers represents one of the most promising frontiers of technological innovation. However, facing challenges and moving toward future directions requires strategic vision and ongoing commitment.

Let's look at some of the main aspects to consider:

- Materials Development: One of the main hurdles is finding a balance between biodegradability and the essential mechanical properties of materials, such as strength and flexibility. In addition, maximizing the printability of biodegradable polymers involves fine-tuning parameters such as temperature, printing speed and height of layer. Each variable must be optimized to ensure satisfactory and functional results.

- Environmental Assessment: Another crucial challenge is the comprehensive assessment of the environmental impact of biodegradable products. It is critical to consider the entire life cycle of the product, from energy consumption to the production of greenhouse gas emissions to other environmental implications. Only a holistic assessment can ensure that the benefits of biodegradability outweigh the environmental costs.

- Technology and Compatibility: 3D printing objects with multiple biodegradable materials requires advances in both printer technology and material compatibility. In addition, developing efficient recycling processes for 3D printed objects is essential to minimize waste and close the material loop, making production more sustainable.

- Medical Applications: The use of biodegradable materials in 3D printing for medical applications, such as implants, drug delivery systems, and tissue engineering, offers significant potential benefits. However, it is critical to ensure that these materials are biocompatible and safe for use in the human body.

- Technology and Monitoring: The integration of IoT technologies and sensors into 3D printed biodegradable products can revolutionize monitoring and data collection. These technologies have potential applications in areas such as agriculture and environmental monitoring, improving product traceability and effectiveness.

- Post-Processing: The development of environmentally friendly post-processing techniques is crucial. It is necessary to ensure that these techniques do not compromise the biodegradability of the material while maintaining the integrity and performance of the finished products.

- Machine Learning: Machine learning has the potential to revolutionize 3D printing of biodegradable polymers. However, there are significant challenges, such as the lack of large and diverse datasets to train machine learning models. It is essential to collect comprehensive data on polymer materials, print settings and environmental conditions. In addition, machine learning models must be able to quickly optimize and modify print settings in real time to correct errors and inconsistencies.

Research and the Future

The future of 3D printing of biodegradable polymers will depend on continued research into advanced materials, multi-material printing, and improved recycling processes. Exploring the use of these materials in medical applications is promising, as is improving the economic efficiency and scalability of manufacturing. Research will aim to develop complex and functional structures, with an increasing focus on sustainability.

The integration of machine learning into 3D printing can optimize printing parameters and enable the creation of tailored materials with specific qualities for different applications. This technology could make the production of biodegradable materials more sustainable and economical, opening up new opportunities in various industries.

Conclusions

In summary, the combination of 3D printing and machine learning in biodegradable polymers represents a significant evolution toward more sustainable and innovative manufacturing processes. These technologies offer opportunities to create advanced and customized materials while improving efficiency and reducing environmental impact. Despite challenges such as material consistency and scalability, the synergy between these technologies promises a greener and more sustainable future in industrial manufacturing.

For more details on the study, please rely on the original article. References here:

S.A.V. Dananjaya, V.S. Chevali, J.P. Dear, P. Potluri, C. Abeykoon,

3D printing of biodegradable polymers and their composites - Current state-of-the-art, properties, applications, and machine learning for potential future applications,

Progress in Materials Science,

Volume 146,

2024,

101336,

ISSN 0079-6425,

https://doi.org/10.1016/j.pmatsci.2024.101336.

(https://www.sciencedirect.com/science/article/pii/S0079642524001051)

All references are available in the original project on which this article is based. All copyright details can be found in the reference project. Please contact us for further details.